Latest parallel plate capacitor capacitance specifications

Latest Parallel Plate Capacitor Capacitance Specifications

I. Introduction

In the realm of electrical engineering, capacitors play a pivotal role in the functioning of various electronic devices. Among the different types of capacitors, the parallel plate capacitor stands out due to its simplicity and effectiveness. This blog post aims to delve into the latest specifications and trends surrounding parallel plate capacitors, shedding light on their fundamental principles, factors affecting capacitance, recent advancements, applications, challenges, and future directions.

II. Fundamentals of Parallel Plate Capacitors

A. Basic Structure and Components

A parallel plate capacitor consists of two conductive plates separated by a dielectric material. The plates are typically made of metals such as aluminum or copper, while the dielectric can be air, plastic, ceramic, or other insulating materials. The arrangement of these components allows the capacitor to store electrical energy in the electric field created between the plates.

B. Capacitance Formula

The capacitance (C) of a parallel plate capacitor is defined by the formula:

\[ C = \frac{ε(A)}{d} \]

Where:

- \( C \) is the capacitance measured in farads (F),

- \( ε \) is the permittivity of the dielectric material,

- \( A \) is the area of one of the plates, and

- \( d \) is the distance between the plates.

This formula highlights the relationship between the physical characteristics of the capacitor and its ability to store charge.

III. Factors Affecting Capacitance

A. Plate Area

The area of the plates directly influences the capacitance. A larger plate area allows for more charge to be stored, resulting in higher capacitance. In practical design, engineers must balance the size of the capacitor with the space available in electronic devices, often leading to innovative designs that maximize capacitance without increasing size excessively.

B. Distance Between Plates

The distance between the plates is inversely related to capacitance. As the distance increases, the capacitance decreases. This relationship necessitates careful design considerations, as reducing the distance can lead to increased capacitance but may also raise the risk of dielectric breakdown, where the insulating material fails and allows current to flow between the plates.

C. Dielectric Material

The choice of dielectric material is crucial in determining the performance of a parallel plate capacitor. Different materials have varying dielectric constants, which affect the capacitor's ability to store charge. Common dielectric materials include ceramic, polyester, and tantalum, each offering unique properties that can enhance capacitance and overall performance.

IV. Latest Specifications and Trends in Parallel Plate Capacitors

A. Advances in Dielectric Materials

Recent advancements in dielectric materials have significantly impacted the specifications of parallel plate capacitors. High-k dielectrics, which have a high dielectric constant, allow for greater capacitance in smaller packages. These materials are particularly beneficial in applications where space is at a premium, such as in smartphones and other compact electronic devices.

Additionally, organic and composite dielectrics are gaining traction due to their lightweight and flexible properties. These materials not only enhance capacitance but also open up new possibilities for applications in wearable technology and flexible electronics.

B. Miniaturization and Its Impact on Capacitance

The trend toward miniaturization in electronics has led to the development of smaller parallel plate capacitors. While this trend poses challenges in maintaining capacitance values, innovative designs and materials have enabled manufacturers to produce capacitors that meet the demands of modern devices without compromising performance.

C. Industry Standards and Specifications

As technology evolves, so do the industry standards governing capacitor specifications. Organizations such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) continuously update their guidelines to reflect the latest advancements. Manufacturers often adhere to these standards to ensure compatibility and reliability across various applications.

V. Applications of Parallel Plate Capacitors

A. Consumer Electronics

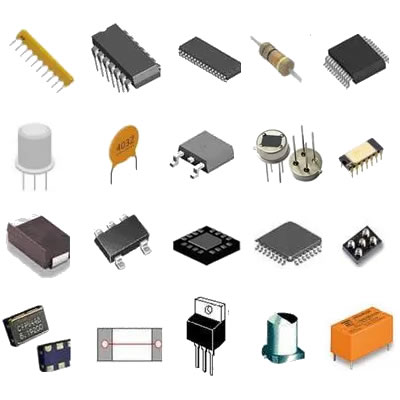

Parallel plate capacitors are ubiquitous in consumer electronics, playing a vital role in smartphones, tablets, and laptops. They are used in power supply circuits, signal processing, and energy storage, contributing to the overall performance and efficiency of these devices.

B. Industrial Applications

In industrial settings, parallel plate capacitors are employed in power systems and machinery. They help regulate voltage, filter signals, and store energy, ensuring the smooth operation of various processes. Their reliability and efficiency make them essential components in many industrial applications.

C. Emerging Technologies

The rise of renewable energy systems and electric vehicles has created new opportunities for parallel plate capacitors. In renewable energy applications, they are used for energy storage and management, while in electric vehicles, they play a crucial role in battery systems, enhancing performance and efficiency.

VI. Challenges and Limitations

A. Physical Limitations of Parallel Plate Capacitors

Despite their advantages, parallel plate capacitors face physical limitations. Size constraints can hinder their application in compact devices, while heat dissipation issues can affect performance and reliability. Engineers must navigate these challenges to optimize capacitor design.

B. Performance Limitations

Performance limitations, such as voltage ratings and breakdown, are critical considerations in capacitor design. As capacitors age, their performance can degrade, leading to reliability concerns. Manufacturers are continually working to improve the longevity and performance of parallel plate capacitors to address these issues.

VII. Future Directions in Parallel Plate Capacitor Technology

A. Research and Development Trends

The future of parallel plate capacitors is promising, with ongoing research and development focused on materials science and innovative designs. Researchers are exploring new dielectric materials and configurations that could enhance capacitance and performance, paving the way for next-generation capacitors.

B. Predictions for Capacitance Specifications

As technology continues to advance, we can expect significant improvements in capacitance values. Future industry standards will likely reflect these advancements, ensuring that parallel plate capacitors remain integral to modern electronic devices.

VIII. Conclusion

In summary, parallel plate capacitors are essential components in the world of electrical engineering, with their capacitance specifications playing a crucial role in various applications. Understanding the fundamentals, factors affecting capacitance, and the latest trends is vital for engineers and manufacturers alike. As technology evolves, staying updated with specifications and advancements will be key to harnessing the full potential of parallel plate capacitors in the future.

IX. References

1. Academic Journals

2. Industry Reports

3. Standards Organizations Publications

This blog post provides a comprehensive overview of the latest specifications and trends in parallel plate capacitors, ensuring that readers are well-informed about this critical component in modern electronics.