What are the product standards for Farara capacitors?

What are the Product Standards for Farara Capacitors?

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. They are essential in various applications, from consumer electronics to industrial machinery. Among the many manufacturers in the capacitor market, Farara capacitors have gained recognition for their quality and reliability. This article aims to explore the product standards that govern Farara capacitors, shedding light on their significance in ensuring performance and safety.

II. Understanding Capacitor Standards

A. Definition of Product Standards in Electronics

Product standards in electronics refer to the established criteria and guidelines that products must meet to ensure safety, reliability, and performance. These standards are developed by various organizations and are crucial for manufacturers to follow, as they help maintain consistency and quality across products.

B. Importance of Adhering to Product Standards

Adhering to product standards is vital for several reasons. Firstly, it ensures that products are safe for consumers and do not pose any hazards. Secondly, compliance with standards can enhance a company's reputation and marketability. Lastly, it facilitates international trade by ensuring that products meet the requirements of different markets.

C. Overview of International and National Standards Organizations

Several organizations are responsible for developing and maintaining product standards in the electronics industry. The International Electrotechnical Commission (IEC) sets global standards for electrical and electronic devices. The American National Standards Institute (ANSI) oversees the development of standards in the United States, while Underwriters Laboratories (UL) focuses on product safety testing and certification. These organizations play a crucial role in ensuring that manufacturers, including Farara, adhere to established standards.

III. Farara Capacitors: Company Background

A. Brief History of Farara

Farara has established itself as a reputable manufacturer of capacitors, with a history that spans several decades. The company has consistently focused on innovation and quality, positioning itself as a leader in the capacitor market.

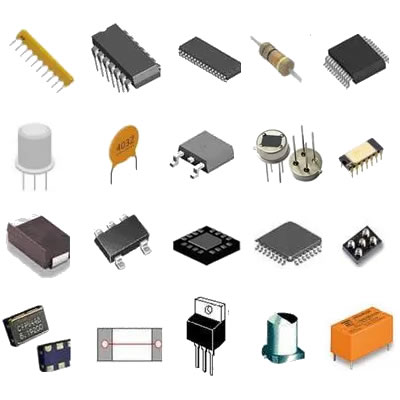

B. Types of Capacitors Produced by Farara

Farara produces a wide range of capacitors, including ceramic, electrolytic, film, and tantalum capacitors. Each type serves different applications and industries, showcasing Farara's versatility and commitment to meeting diverse customer needs.

C. Market Position and Reputation in the Industry

Farara's commitment to quality and adherence to product standards has earned it a strong reputation in the industry. The company is known for its reliable products and has built long-lasting relationships with clients across various sectors.

IV. Product Standards for Farara Capacitors

A. Overview of Specific Standards Applicable to Farara Capacitors

Farara capacitors are subject to several international and national standards that ensure their quality and safety.

1. International Electrotechnical Commission (IEC) Standards

Farara capacitors comply with IEC standards, which cover various aspects of capacitor design, testing, and performance. These standards ensure that the capacitors can operate safely and effectively in their intended applications.

2. American National Standards Institute (ANSI) Standards

In addition to IEC standards, Farara adheres to ANSI standards, which are particularly relevant for products sold in the United States. Compliance with ANSI standards ensures that Farara capacitors meet the specific requirements of the U.S. market.

3. Underwriters Laboratories (UL) Standards

Farara capacitors are also tested and certified by UL, a leading safety certification organization. UL standards focus on product safety and performance, providing assurance to consumers and manufacturers alike.

B. Compliance with RoHS (Restriction of Hazardous Substances)

Farara is committed to environmental sustainability and complies with the RoHS directive, which restricts the use of hazardous substances in electrical and electronic equipment. This compliance ensures that Farara capacitors are safe for both consumers and the environment.

C. Compliance with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals)

In addition to RoHS, Farara adheres to REACH regulations, which aim to protect human health and the environment from the risks posed by chemicals. This compliance further underscores Farara's commitment to safety and sustainability.

V. Testing and Quality Assurance

A. Description of Testing Procedures for Farara Capacitors

Farara employs rigorous testing procedures to ensure the quality and reliability of its capacitors.

1. Electrical Testing

Electrical testing involves assessing the performance of capacitors under various electrical conditions. This testing ensures that the capacitors meet their specified capacitance, voltage ratings, and other electrical characteristics.

2. Environmental Testing

Environmental testing evaluates how capacitors perform under different environmental conditions, such as temperature and humidity. This testing is crucial for ensuring that capacitors can operate reliably in real-world applications.

3. Mechanical Testing

Mechanical testing assesses the physical durability of capacitors, including their resistance to vibration, shock, and other mechanical stresses. This testing helps ensure that Farara capacitors can withstand the rigors of their intended applications.

B. Quality Assurance Processes in Place at Farara

Farara has implemented comprehensive quality assurance processes to monitor and maintain product quality throughout the manufacturing process. These processes include regular audits, inspections, and continuous improvement initiatives.

C. Certifications and Accreditations Held by Farara

Farara holds various certifications and accreditations that demonstrate its commitment to quality and compliance with industry standards. These certifications provide assurance to customers regarding the reliability and safety of Farara capacitors.

VI. Performance Characteristics

A. Key Performance Metrics for Farara Capacitors

Farara capacitors are designed to meet specific performance metrics that are critical for their applications.

1. Capacitance Range

Farara offers a wide capacitance range, allowing customers to select capacitors that meet their specific needs. This versatility is essential for various applications, from low-power devices to high-performance systems.

2. Voltage Ratings

Voltage ratings are crucial for ensuring that capacitors can operate safely within their intended voltage range. Farara capacitors are designed to meet stringent voltage requirements, providing reliability in demanding applications.

3. Temperature Coefficients

Temperature coefficients indicate how a capacitor's performance changes with temperature. Farara capacitors are engineered to maintain stable performance across a range of temperatures, ensuring reliability in diverse environments.

B. Comparison with Industry Standards

Farara capacitors consistently meet or exceed industry standards for performance characteristics. This commitment to quality ensures that customers can rely on Farara products for their applications.

C. Importance of Performance Characteristics in Applications

The performance characteristics of capacitors are critical for their effectiveness in various applications. Adhering to product standards ensures that Farara capacitors deliver the reliability and performance that customers expect.

VII. Applications of Farara Capacitors

A. Overview of Industries Using Farara Capacitors

Farara capacitors are utilized across a wide range of industries, including:

1. Consumer Electronics

In consumer electronics, Farara capacitors are used in devices such as smartphones, televisions, and computers, where reliability and performance are paramount.

2. Automotive

In the automotive industry, Farara capacitors play a crucial role in electronic control units, infotainment systems, and safety features, ensuring that vehicles operate safely and efficiently.

3. Industrial Applications

Farara capacitors are also used in various industrial applications, including power supplies, motor drives, and automation systems, where high performance and durability are essential.

B. Specific Applications and Case Studies

Farara capacitors have been successfully implemented in numerous projects, showcasing their versatility and reliability. Case studies highlight their effectiveness in enhancing the performance of electronic systems across different sectors.

C. Importance of Product Standards in Ensuring Reliability and Safety

Product standards are vital in ensuring that Farara capacitors perform reliably and safely in their applications. Compliance with these standards provides assurance to customers and helps prevent potential failures.

VIII. Challenges and Future Directions

A. Challenges in Maintaining Product Standards in a Rapidly Evolving Market

The electronics industry is constantly evolving, with new technologies and applications emerging regularly. Maintaining product standards in this dynamic environment presents challenges for manufacturers like Farara, who must adapt to changing requirements and expectations.

B. Future Trends in Capacitor Technology and Standards

As technology advances, new trends in capacitor design and manufacturing are likely to emerge. These trends may include the development of more efficient materials, miniaturization, and enhanced performance characteristics.

C. Farara's Commitment to Innovation and Compliance

Farara is committed to staying at the forefront of capacitor technology while ensuring compliance with evolving product standards. This commitment to innovation and quality positions Farara for continued success in the industry.

IX. Conclusion

In conclusion, product standards play a crucial role in ensuring the quality and reliability of Farara capacitors. By adhering to international and national standards, Farara demonstrates its commitment to safety, performance, and customer satisfaction. As the electronics industry continues to evolve, understanding and maintaining these standards will be essential for manufacturers and consumers alike. Further research and exploration of capacitor standards can provide valuable insights into the future of this critical component in electronic systems.

X. References

- International Electrotechnical Commission (IEC) Standards

- American National Standards Institute (ANSI) Standards

- Underwriters Laboratories (UL) Standards

- RoHS Directive

- REACH Regulations

- Farara Capacitors Company Website

- Industry Publications on Capacitor Technology and Standards

This comprehensive exploration of the product standards for Farara capacitors highlights the importance of quality and compliance in the electronics industry, ensuring that these essential components meet the needs of various applications while maintaining safety and reliability.