What are the mainstream models of motor capacitors?

What are the Mainstream Models of Motor Capacitors?

I. Introduction

A. Definition of Motor Capacitors

Motor capacitors are electrical components that store and release electrical energy in electric motors. They play a crucial role in enhancing the performance and efficiency of motors by providing the necessary phase shift for starting and running operations.

B. Importance of Motor Capacitors in Electrical Systems

In electrical systems, motor capacitors are essential for various applications, including HVAC systems, pumps, and industrial machinery. They help improve the starting torque of motors, stabilize voltage, and reduce energy consumption, making them vital for efficient motor operation.

C. Overview of the Article's Purpose

This article aims to provide a comprehensive overview of motor capacitors, including their types, mainstream models, and selection criteria. By understanding these components, readers can make informed decisions when choosing motor capacitors for their specific applications.

II. Understanding Motor Capacitors

A. What is a Motor Capacitor?

1. Function and Role in Electric Motors

Motor capacitors serve two primary functions: starting and running. Start capacitors provide an initial boost of energy to help the motor overcome inertia and start turning. Once the motor reaches a certain speed, run capacitors take over to maintain efficient operation.

2. Types of Motors that Use Capacitors

Capacitors are commonly used in single-phase induction motors, which are prevalent in household appliances, fans, and small machinery. They are also found in some three-phase motors, particularly in applications requiring phase shift for improved performance.

B. Basic Principles of Operation

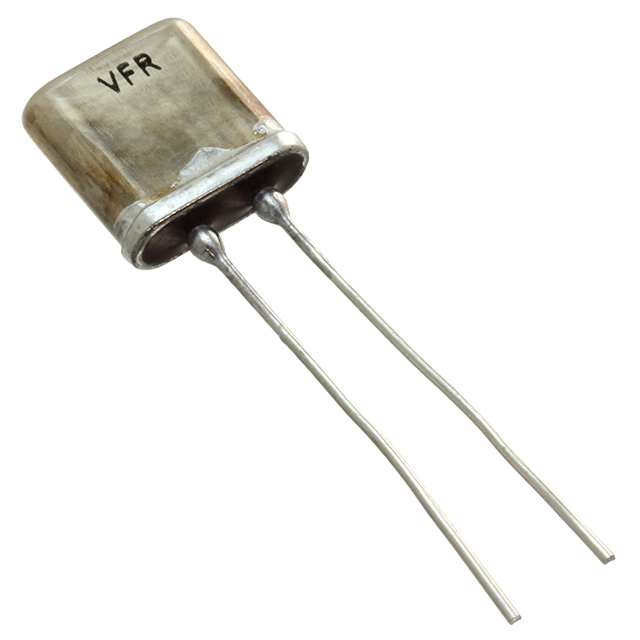

1. Capacitance and Electrical Charge

Capacitance is the ability of a capacitor to store electrical charge. It is measured in farads (F) and determines how much energy the capacitor can store. The higher the capacitance, the more energy it can provide to the motor.

2. Phase Shift and Torque Generation

Capacitors create a phase shift in the electrical current, which is essential for generating torque in motors. This phase shift allows the motor to start and run smoothly, improving overall efficiency and performance.

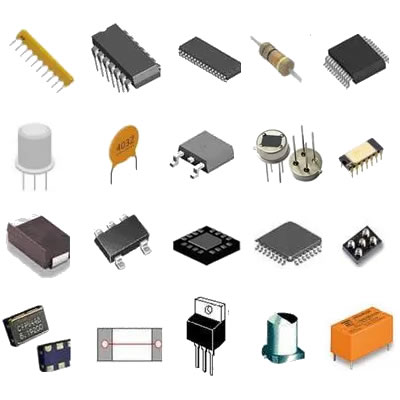

III. Types of Motor Capacitors

A. Start Capacitors

1. Purpose and Function

Start capacitors are designed to provide a temporary boost of energy to start the motor. They are typically used in applications where high starting torque is required.

2. Characteristics and Specifications

Start capacitors usually have a higher capacitance value than run capacitors and are rated for short-term use. They are often rated for voltages between 120V and 600V.

3. Common Applications

Common applications for start capacitors include air conditioning units, refrigeration compressors, and small electric motors.

B. Run Capacitors

1. Purpose and Function

Run capacitors are used to improve the efficiency of a motor during its normal operation. They provide a continuous supply of energy to maintain the motor's performance.

2. Characteristics and Specifications

Run capacitors typically have a lower capacitance value than start capacitors and are designed for continuous use. They are rated for voltages similar to start capacitors.

3. Common Applications

Run capacitors are commonly found in HVAC systems, ceiling fans, and other appliances that require consistent motor operation.

C. Dual-Run Capacitors

1. Definition and Functionality

Dual-run capacitors combine the functions of both start and run capacitors in a single unit. They are designed to provide the necessary energy for both starting and running the motor.

2. Characteristics and Specifications

These capacitors are typically rated for higher capacitance values and voltages, making them suitable for a wide range of applications.

3. Common Applications

Dual-run capacitors are often used in larger HVAC systems, commercial refrigeration units, and industrial motors.

IV. Mainstream Models of Motor Capacitors

A. Overview of Popular Brands and Models

Several manufacturers produce high-quality motor capacitors, each offering various models with unique features and specifications. Some of the most recognized brands include:

1. **MARS**: Known for its reliable and durable capacitors, MARS offers a wide range of start, run, and dual-run capacitors.

2. **GE**: General Electric provides high-performance capacitors suitable for various industrial and commercial applications.

3. **Dayton**: Dayton capacitors are known for their robust construction and efficiency, making them a popular choice among professionals.

B. Specific Models

1. Model A: MARS 12600

Description: A dual-run capacitor with a capacitance of 35/5 µF and a voltage rating of 370V.

Features: This model features a durable metal canister and is designed for long-term use in HVAC systems.

Applications: Ideal for air conditioning units and heat pumps.

2. Model B: GE 97F

Description: A start capacitor with a capacitance of 70 µF and a voltage rating of 250V.

Features: This model is designed for high starting torque applications and features a compact design.

Applications: Commonly used in small motors and compressors.

3. Model C: Dayton 4MZ44

Description: A run capacitor with a capacitance of 10 µF and a voltage rating of 370V.

Features: This model is known for its reliability and efficiency, with a long lifespan.

Applications: Suitable for ceiling fans and small appliances.

C. Emerging Technologies and Innovations

1. Advancements in Capacitor Design

Recent advancements in capacitor technology have led to the development of more efficient and compact designs. Innovations such as improved dielectric materials and enhanced manufacturing processes have resulted in capacitors with higher performance and longer lifespans.

2. Eco-Friendly Options

With increasing environmental concerns, manufacturers are also focusing on eco-friendly capacitor options. These capacitors are designed to minimize energy consumption and reduce waste, making them a sustainable choice for modern applications.

V. Selecting the Right Motor Capacitor

A. Factors to Consider

When selecting a motor capacitor, several factors must be considered to ensure optimal performance:

1. Voltage Rating

The voltage rating of the capacitor must match or exceed the voltage of the motor to prevent failure.

2. Capacitance Value

Choosing the correct capacitance value is crucial for the motor's performance. Using a capacitor with the wrong capacitance can lead to inefficient operation or damage.

3. Temperature Rating

Capacitors are rated for specific temperature ranges. Selecting a capacitor with an appropriate temperature rating ensures reliable performance in various operating conditions.

4. Physical Size and Mounting

The physical size and mounting style of the capacitor should be compatible with the motor's design to facilitate easy installation.

B. Common Mistakes to Avoid

1. Underestimating Capacitor Ratings

One common mistake is underestimating the required ratings for voltage and capacitance. This can lead to premature failure and costly repairs.

2. Ignoring Manufacturer Specifications

Always refer to the manufacturer's specifications when selecting a capacitor. Ignoring these guidelines can result in compatibility issues and reduced performance.

VI. Maintenance and Troubleshooting

A. Signs of a Failing Capacitor

1. Symptoms in Motor Performance

A failing capacitor may cause the motor to run inefficiently, produce unusual noises, or fail to start altogether. Monitoring these symptoms can help identify potential issues early.

2. Visual Inspection Tips

Regular visual inspections can help detect signs of capacitor failure, such as bulging, leaking, or discoloration. If any of these signs are present, the capacitor should be replaced immediately.

B. Replacement Procedures

1. Safety Precautions

Before replacing a capacitor, always disconnect the power supply and discharge the capacitor to prevent electrical shock.

2. Step-by-Step Replacement Guide

1. Disconnect the power supply to the motor.

2. Remove the old capacitor from its mounting.

3. Install the new capacitor, ensuring proper connections.

4. Reconnect the power supply and test the motor.

VII. Conclusion

A. Recap of Key Points

Motor capacitors are essential components in electric motors, providing the necessary energy for starting and running operations. Understanding the different types of capacitors and their applications is crucial for selecting the right one for specific needs.

B. The Importance of Choosing the Right Capacitor

Choosing the correct motor capacitor can significantly impact the efficiency and longevity of the motor. By considering factors such as voltage rating, capacitance value, and temperature rating, users can ensure optimal performance.

C. Future Trends in Motor Capacitor Technology

As technology continues to advance, we can expect to see further innovations in motor capacitor design, including more efficient and eco-friendly options. Staying informed about these trends will help users make better choices for their electrical systems.

VIII. References

A. Citing Relevant Literature and Resources

1. "Electric Motor Repair" by Robert Rosenberg

2. "Capacitors: Principles and Applications" by John Smith

3. Manufacturer websites for MARS, GE, and Dayton

B. Additional Reading for Further Exploration

1. Articles on capacitor technology advancements

2. Guides on motor maintenance and troubleshooting

By understanding the various aspects of motor capacitors, readers can make informed decisions that enhance the performance and efficiency of their electrical systems.