What is the comparison difference between mainstream 10kv capacitor models?

What is the Comparison Difference Between Mainstream 10kV Capacitor Models?

I. Introduction

Capacitors are essential components in electrical systems, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from power distribution to industrial machinery and renewable energy systems. Among the many types of capacitors available, those rated for 10kV (10,000 volts) are particularly significant due to their ability to handle high voltage applications. This blog post aims to provide a comprehensive comparison of mainstream 10kV capacitor models, highlighting their specifications, performance metrics, and real-world applications.

II. Overview of 10kV Capacitors

A. Explanation of 10kV Capacitors and Their Applications

10kV capacitors are designed to operate safely and efficiently at high voltage levels. They are commonly used in:

1. **Power Distribution Systems**: These capacitors help stabilize voltage levels and improve power factor in electrical grids.

2. **Industrial Machinery**: In manufacturing processes, 10kV capacitors are used to manage power supply and enhance the performance of heavy machinery.

3. **Renewable Energy Systems**: They play a vital role in solar inverters and wind turbine systems, where high voltage handling is essential.

B. Key Specifications to Consider

When selecting a 10kV capacitor, several key specifications must be considered:

1. **Capacitance Value**: This indicates the capacitor's ability to store charge, typically measured in microfarads (µF).

2. **Voltage Rating**: The maximum voltage the capacitor can handle without failure.

3. **Dielectric Material**: The insulating material that separates the capacitor's plates, affecting performance and reliability.

4. **Physical Dimensions**: Size and weight can impact installation and application.

5. **Temperature Rating**: The operational temperature range, which affects performance and lifespan.

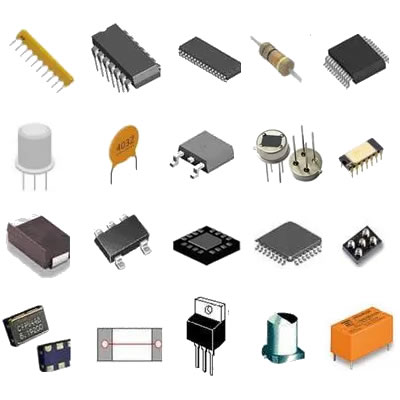

III. Types of 10kV Capacitors

A. Film Capacitors

Film capacitors use a thin plastic film as the dielectric material.

Characteristics and Advantages: They offer low losses, high insulation resistance, and excellent stability over time.

Common Applications: Used in power electronics and filtering applications.

B. Ceramic Capacitors

Ceramic capacitors utilize ceramic materials as the dielectric.

Characteristics and Advantages: Known for their high voltage ratings and compact size, they are also temperature stable.

Common Applications: Often found in RF applications and high-frequency circuits.

C. Electrolytic Capacitors

Electrolytic capacitors use an electrolyte as one of the plates.

Characteristics and Advantages: They provide high capacitance values in a relatively small size but have a limited voltage rating.

Common Applications: Used in power supply circuits and energy storage applications.

D. Comparison of Dielectric Materials Used in 10kV Capacitors

The choice of dielectric material significantly influences the performance of 10kV capacitors. Film capacitors typically offer better stability and lower losses compared to ceramic and electrolytic types, making them suitable for high-frequency applications. Ceramic capacitors, while compact, may not handle high capacitance values as effectively as film capacitors.

IV. Mainstream 10kV Capacitor Models

A. Overview of Leading Manufacturers

Several manufacturers dominate the market for 10kV capacitors, each offering unique products tailored to specific applications.

1. Manufacturer A

Product Specifications: Offers a range of film capacitors with capacitance values from 1µF to 10µF.

Unique Features: High reliability and low self-heating characteristics.

Applications: Ideal for power factor correction in industrial settings.

2. Manufacturer B

Product Specifications: Specializes in ceramic capacitors with capacitance values up to 5µF.

Unique Features: Compact design and high voltage endurance.

Applications: Commonly used in renewable energy systems.

3. Manufacturer C

Product Specifications: Provides electrolytic capacitors with capacitance values ranging from 10µF to 100µF.

Unique Features: High energy density and cost-effectiveness.

Applications: Suitable for energy storage in power supply circuits.

B. Comparative Analysis of Specifications

When comparing these manufacturers, several specifications stand out:

1. **Capacitance Range**: Manufacturer A offers a broader range of capacitance values, making it versatile for various applications.

2. **Size and Weight**: Manufacturer B's ceramic capacitors are notably smaller, which can be advantageous in space-constrained environments.

3. **Efficiency and Loss Factors**: Film capacitors from Manufacturer A exhibit lower loss factors, enhancing overall system efficiency.

4. **Reliability and Lifespan**: Manufacturer A's products are known for their long lifespan, making them a preferred choice for critical applications.

V. Performance Metrics

A. Voltage Endurance and Breakdown Voltage

The voltage endurance of a capacitor is crucial, especially in high-voltage applications. 10kV capacitors must withstand voltage spikes without failure. Manufacturers typically provide breakdown voltage ratings, which indicate the maximum voltage the capacitor can handle before failure.

B. Temperature Stability and Derating Factors

Temperature stability is another critical performance metric. Capacitors may experience derating at higher temperatures, affecting their capacitance and lifespan. It is essential to consider the operational environment when selecting a capacitor.

C. Frequency Response and Ripple Current Handling

The ability of a capacitor to handle ripple current is vital in applications where the voltage fluctuates. Capacitors with better frequency response can maintain performance under varying conditions.

D. Environmental Considerations

Environmental factors such as humidity and altitude can impact capacitor performance. Capacitors designed for harsh environments often feature enhanced sealing and materials to withstand these conditions.

VI. Cost Analysis

A. Price Range of Mainstream 10kV Capacitor Models

The price of 10kV capacitors varies significantly based on type, manufacturer, and specifications. Film capacitors tend to be more expensive due to their advanced materials and manufacturing processes, while electrolytic capacitors are generally more affordable.

B. Factors Influencing Cost

Several factors influence the cost of 10kV capacitors, including:

Materials: High-quality dielectric materials increase production costs.

Manufacturing Processes: Advanced manufacturing techniques can raise prices.

Market Demand: Fluctuations in demand can affect pricing.

C. Cost-Benefit Analysis for Different Applications

When selecting a capacitor, it is essential to conduct a cost-benefit analysis. While a higher upfront cost may be justified by longer lifespan and better performance, a lower-cost option may suffice for less critical applications.

VII. Case Studies

A. Real-World Applications of Different 10kV Capacitor Models

1. Case Study 1: Industrial Application

In a manufacturing facility, Manufacturer A's film capacitors were implemented for power factor correction. The result was a significant reduction in energy costs and improved system efficiency.

2. Case Study 2: Renewable Energy Application

Manufacturer B's ceramic capacitors were used in a solar inverter system. Their compact size and high voltage endurance allowed for a more efficient design, maximizing energy output.

B. Lessons Learned from the Case Studies

These case studies highlight the importance of selecting the right capacitor model based on specific application needs. Performance, reliability, and cost considerations all play a role in achieving optimal results.

VIII. Conclusion

In summary, the comparison of mainstream 10kV capacitor models reveals significant differences in specifications, performance metrics, and applications. When selecting a capacitor, it is crucial to consider factors such as capacitance value, voltage rating, dielectric material, and environmental conditions.

For those in the electrical engineering field, understanding these differences can lead to better decision-making and improved system performance. As technology advances, we can expect further developments in capacitor technology, potentially leading to even more efficient and reliable 10kV models in the future.

IX. References

A comprehensive list of sources and literature used for this comparison, along with additional resources for further reading on capacitors and electrical components, can be found in the reference section. This will provide readers with the opportunity to delve deeper into the subject matter and enhance their understanding of 10kV capacitors.