What are the product standards for parallel capacitors?

What are the Product Standards for Parallel Capacitors?

I. Introduction

A. Definition of Parallel Capacitors

Parallel capacitors are capacitors connected in such a way that their terminals are connected to the same two points in a circuit. This configuration allows the total capacitance to be the sum of the individual capacitances, making it a common practice in electronic circuit design. For instance, if two capacitors of 10 µF and 20 µF are connected in parallel, the total capacitance would be 30 µF.

B. Importance of Product Standards

Product standards are essential in ensuring that electronic components, including capacitors, meet specific safety, performance, and interoperability criteria. These standards help manufacturers produce reliable products and provide consumers with assurance regarding the quality and safety of the components they use.

C. Overview of the Article

This article will explore the product standards for parallel capacitors, including their definitions, the organizations that set these standards, specific requirements, testing and certification processes, challenges in compliance, and future trends in capacitor standards.

II. Understanding Capacitors

A. Basic Principles of Capacitors

1. Definition and Function

A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy.

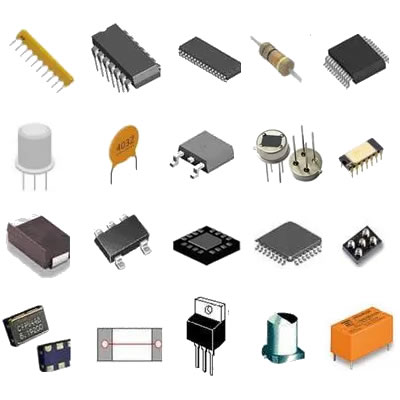

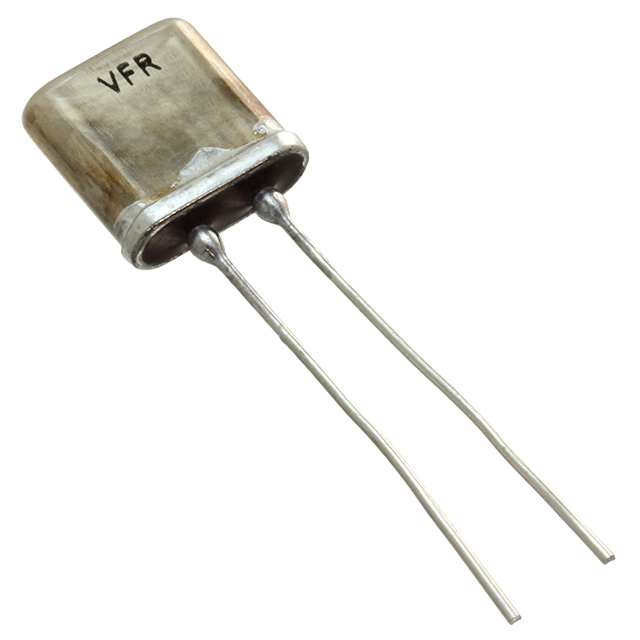

2. Types of Capacitors

There are various types of capacitors, including ceramic, electrolytic, tantalum, and film capacitors, each with unique characteristics and applications. The choice of capacitor type depends on factors such as capacitance value, voltage rating, and intended use in a circuit.

B. Role of Parallel Capacitors in Circuits

1. Capacitance Addition

One of the primary reasons for using parallel capacitors is to increase the total capacitance in a circuit. This is particularly useful in power supply circuits, where larger capacitance values are needed to smooth out voltage fluctuations.

2. Applications in Electronics

Parallel capacitors are widely used in various applications, including power supply filtering, timing circuits, and energy storage systems. Their ability to combine capacitance values makes them versatile components in electronic design.

III. Product Standards Overview

A. Definition of Product Standards

Product standards are established criteria that define the quality, safety, and performance requirements for specific products. These standards are developed by various organizations and are essential for ensuring that products are reliable and safe for consumer use.

B. Importance of Standards in Electronics

1. Safety

Safety is a paramount concern in electronics. Standards help ensure that capacitors can operate safely under specified conditions, reducing the risk of failure that could lead to hazardous situations.

2. Performance

Standards also define performance metrics, ensuring that capacitors function as intended in their applications. This includes specifications for capacitance, voltage ratings, and temperature coefficients.

3. Interoperability

In a world where electronic devices are increasingly interconnected, interoperability is crucial. Standards ensure that components from different manufacturers can work together seamlessly, promoting compatibility and reducing the risk of system failures.

IV. Key Organizations and Standards for Capacitors

A. International Electrotechnical Commission (IEC)

The IEC is a leading organization in developing international standards for electrical and electronic technologies. Key standards for capacitors include:

1. IEC 60384 Series

This series covers fixed capacitors for use in electronic equipment, detailing requirements for performance, safety, and testing.

2. IEC 61071

This standard specifies the requirements for capacitors used in power electronics, focusing on their performance under various operating conditions.

B. Institute of Electrical and Electronics Engineers (IEEE)

The IEEE is another prominent organization that develops standards for electrical and electronic systems. Important standards include:

1. IEEE 18

This standard provides guidelines for the measurement of capacitance and dissipation factor of capacitors.

2. IEEE 62

This standard outlines the requirements for capacitors used in power factor correction applications.

C. American National Standards Institute (ANSI)

ANSI oversees the development of voluntary consensus standards for products, services, and systems in the United States, including those for capacitors.

D. Other Relevant Organizations

1. Underwriters Laboratories (UL)

UL is known for its safety certification and testing services, ensuring that capacitors meet safety standards before they reach the market.

2. European Committee for Electrotechnical Standardization (CENELEC)

CENELEC develops European standards for electrical and electronic products, including capacitors, ensuring compliance with EU regulations.

V. Specific Product Standards for Parallel Capacitors

A. Electrical Characteristics

1. Capacitance Tolerance

Capacitance tolerance defines the acceptable range of deviation from the nominal capacitance value. This is crucial for ensuring that capacitors perform as expected in a circuit.

2. Voltage Rating

The voltage rating indicates the maximum voltage a capacitor can handle without risk of failure. Exceeding this rating can lead to catastrophic failure, making it a critical specification.

3. Temperature Coefficient

The temperature coefficient describes how capacitance changes with temperature. This characteristic is vital for applications where temperature fluctuations are expected.

B. Mechanical Characteristics

1. Size and Form Factor

The physical dimensions and form factor of capacitors must meet specific standards to ensure compatibility with circuit designs and mounting methods.

2. Mounting and Connection Standards

Standards for mounting and connection ensure that capacitors can be easily integrated into various electronic assemblies without compromising performance.

C. Environmental Standards

1. RoHS Compliance

The Restriction of Hazardous Substances (RoHS) directive limits the use of specific hazardous materials in electronic products, including capacitors. Compliance with RoHS is essential for manufacturers targeting the European market.

2. End-of-Life Disposal Regulations

Standards for end-of-life disposal ensure that capacitors can be disposed of safely and responsibly, minimizing environmental impact.

VI. Testing and Certification

A. Testing Methods for Capacitors

1. Capacitance Measurement

Capacitance measurement is a fundamental test to verify that a capacitor meets its specified capacitance value.

2. Insulation Resistance Testing

This test measures the resistance of the dielectric material to ensure it can effectively isolate the conductive plates.

3. Dielectric Strength Testing

Dielectric strength testing assesses the capacitor's ability to withstand high voltages without breaking down.

B. Certification Processes

1. Importance of Certification

Certification provides assurance that capacitors meet established standards for safety and performance, instilling confidence in manufacturers and consumers alike.

2. Common Certification Marks

Common certification marks include UL, CE, and RoHS, which indicate compliance with relevant safety and environmental standards.

VII. Challenges in Meeting Product Standards

A. Variability in Manufacturing

Manufacturing variability can lead to inconsistencies in capacitor performance, making it challenging to meet strict product standards.

B. Technological Advancements

Rapid technological advancements can outpace existing standards, necessitating continuous updates to ensure relevance and effectiveness.

C. Global Market Considerations

Navigating different standards across global markets can be complex for manufacturers, requiring a thorough understanding of regional regulations.

VIII. Future Trends in Capacitor Standards

A. Emerging Technologies

As new technologies emerge, such as electric vehicles and renewable energy systems, capacitor standards will need to evolve to address the unique requirements of these applications.

B. Sustainability and Environmental Impact

There is a growing emphasis on sustainability in electronics, leading to the development of standards that promote environmentally friendly materials and practices.

C. Standardization in a Global Market

As the electronics market becomes increasingly globalized, there will be a push for harmonization of standards to facilitate international trade and ensure product safety.

IX. Conclusion

A. Recap of the Importance of Standards

Product standards play a crucial role in ensuring the safety, performance, and interoperability of parallel capacitors in electronic circuits.

B. The Role of Standards in Ensuring Quality and Safety

By adhering to established standards, manufacturers can produce high-quality capacitors that meet consumer expectations and regulatory requirements.

C. Final Thoughts on the Future of Parallel Capacitor Standards

As technology continues to advance, the standards governing parallel capacitors will need to adapt to new challenges and opportunities, ensuring that these essential components remain reliable and safe in an ever-evolving electronic landscape.

X. References

A. List of Relevant Standards and Guidelines

1. IEC 60384 Series

2. IEEE 18

3. RoHS Directive

B. Suggested Further Reading on Capacitors and Standards

1. "Capacitors: Technology and Applications" by John Smith

2. "Understanding Capacitor Standards" by Jane Doe

This comprehensive overview of product standards for parallel capacitors highlights their significance in the electronics industry, ensuring that these vital components meet the necessary safety and performance criteria.