What are the main application directions of ceramic capacitors?

What are the Main Application Directions of Ceramic Capacitors?

I. Introduction

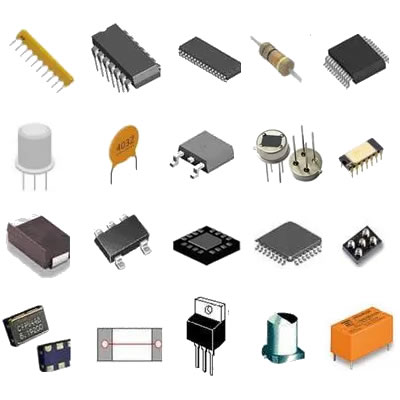

Ceramic capacitors are essential components in modern electronics, known for their reliability, stability, and versatility. These passive electronic components store and release electrical energy, playing a crucial role in various applications across multiple industries. As technology continues to advance, the demand for efficient and compact capacitors has surged, making ceramic capacitors a popular choice among engineers and designers. This article will explore the main application directions of ceramic capacitors, highlighting their significance in consumer electronics, automotive systems, industrial applications, telecommunications, medical devices, and renewable energy systems.

II. Types of Ceramic Capacitors

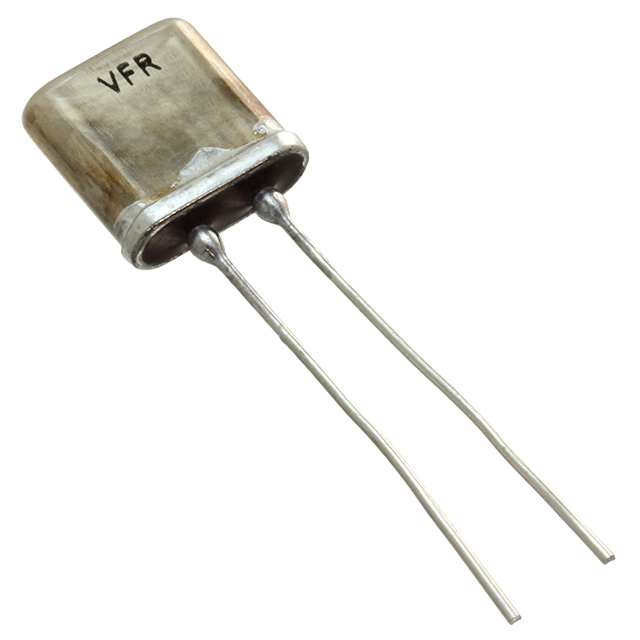

Before delving into specific applications, it is essential to understand the two primary types of ceramic capacitors: Class 1 and Class 2.

A. Class 1 Ceramic Capacitors

Class 1 ceramic capacitors are characterized by their stability and low loss. They typically have a dielectric constant of less than 100 and exhibit minimal capacitance change with temperature and voltage. These capacitors are ideal for applications requiring precision and reliability.

1. Characteristics

- High stability and low drift

- Low dielectric loss

- Suitable for high-frequency applications

2. Common Applications

Class 1 capacitors are commonly used in timing circuits, oscillators, and RF applications where precision is critical.

B. Class 2 Ceramic Capacitors

Class 2 ceramic capacitors, on the other hand, have a higher dielectric constant, allowing for greater capacitance in a smaller package. However, they exhibit more significant variations in capacitance with temperature and voltage.

1. Characteristics

- Higher capacitance values

- Greater variation in capacitance with temperature and voltage

- Suitable for decoupling and filtering applications

2. Common Applications

Class 2 capacitors are widely used in power supply circuits, decoupling applications, and signal filtering.

III. Consumer Electronics

Ceramic capacitors play a vital role in consumer electronics, where compact size and efficiency are paramount.

A. Smartphones and Tablets

In smartphones and tablets, ceramic capacitors are integral to power management and signal filtering.

1. Role in Power Management

These capacitors help regulate voltage levels, ensuring that devices operate efficiently and reliably. They are used in power supply circuits to smooth out voltage fluctuations, providing stable power to various components.

2. Signal Filtering Applications

Ceramic capacitors are also employed in signal filtering applications, helping to eliminate noise and interference in audio and video signals, thereby enhancing the overall user experience.

B. Laptops and Desktops

In laptops and desktops, ceramic capacitors are utilized in various applications, including power supply circuits and audio/video components.

1. Use in Power Supply Circuits

Ceramic capacitors are essential in power supply circuits, where they help stabilize voltage and improve efficiency. Their low ESR (Equivalent Series Resistance) makes them ideal for high-frequency applications.

2. Applications in Audio and Video Components

In audio and video components, ceramic capacitors are used for filtering and decoupling, ensuring high-quality signal transmission and reducing distortion.

IV. Automotive Applications

The automotive industry has increasingly adopted ceramic capacitors, particularly in electric and hybrid vehicles and advanced driver assistance systems (ADAS).

A. Electric and Hybrid Vehicles

In electric and hybrid vehicles, ceramic capacitors play a crucial role in energy storage and management.

1. Energy Storage and Management

These capacitors are used in energy storage systems, helping to manage power flow and improve overall efficiency. They can store energy during regenerative braking and release it when needed, enhancing vehicle performance.

2. Role in Electric Drive Systems

Ceramic capacitors are also employed in electric drive systems, where they help smooth out voltage fluctuations and ensure stable operation of electric motors.

B. Advanced Driver Assistance Systems (ADAS)

ADAS relies heavily on ceramic capacitors for signal processing and filtering.

1. Signal Processing and Filtering

In ADAS, ceramic capacitors are used to filter signals from various sensors, ensuring accurate data processing and enhancing the safety and reliability of the system.

2. Safety and Reliability Considerations

The stability and reliability of ceramic capacitors make them ideal for critical automotive applications, where failure is not an option.

V. Industrial Applications

Ceramic capacitors are widely used in industrial applications, particularly in automation, control systems, and robotics.

A. Automation and Control Systems

In automation and control systems, ceramic capacitors are essential for sensors and actuators.

1. Use in Sensors and Actuators

These capacitors help stabilize voltage levels and filter noise in sensor circuits, ensuring accurate readings and reliable operation.

2. Role in Power Supply Circuits

Ceramic capacitors are also used in power supply circuits within industrial equipment, helping to maintain stable operation and improve efficiency.

B. Robotics

In robotics, ceramic capacitors are crucial for control systems and communication systems.

1. Applications in Control Systems

Ceramic capacitors are used in control systems to filter signals and stabilize voltage, ensuring precise control of robotic movements.

2. Importance in Communication Systems

In communication systems, ceramic capacitors help maintain signal integrity, enabling reliable communication between robotic components.

VI. Telecommunications

The telecommunications industry relies heavily on ceramic capacitors for various applications, including base stations and consumer communication devices.

A. Base Stations and Network Infrastructure

In base stations, ceramic capacitors are used for signal filtering and decoupling.

1. Signal Filtering and Decoupling

These capacitors help eliminate noise and interference in RF signals, ensuring clear and reliable communication.

2. Role in RF Applications

Ceramic capacitors are essential in RF applications, where their stability and low loss characteristics are critical for maintaining signal integrity.

B. Consumer Communication Devices

In consumer communication devices, ceramic capacitors are used in modems and routers.

1. Use in Modems and Routers

Ceramic capacitors help stabilize voltage levels and filter signals, ensuring reliable performance in data transmission.

2. Importance in Signal Integrity

Maintaining signal integrity is crucial in communication devices, and ceramic capacitors play a vital role in achieving this goal.

VII. Medical Devices

Ceramic capacitors are increasingly used in medical devices, where precision and reliability are paramount.

A. Diagnostic Equipment

In diagnostic equipment, ceramic capacitors are essential for imaging systems and patient monitoring devices.

1. Role in Imaging Systems

These capacitors help stabilize voltage levels and filter signals in imaging systems, ensuring high-quality images for accurate diagnosis.

2. Importance in Patient Monitoring Devices

In patient monitoring devices, ceramic capacitors are used to filter signals and maintain stable operation, ensuring reliable monitoring of vital signs.

B. Therapeutic Devices

Ceramic capacitors are also used in therapeutic devices, particularly in implantable devices and medical imaging.

1. Applications in Implantable Devices

In implantable devices, ceramic capacitors help manage power and ensure reliable operation, which is critical for patient safety.

2. Role in Medical Imaging

In medical imaging, ceramic capacitors are used to filter signals and stabilize voltage levels, ensuring high-quality imaging for accurate diagnosis.

VIII. Renewable Energy Systems

As the world shifts towards renewable energy, ceramic capacitors are becoming increasingly important in solar and wind energy systems.

A. Solar Power Systems

In solar power systems, ceramic capacitors are used in inverters and converters.

1. Use in Inverters and Converters

These capacitors help stabilize voltage levels and filter signals, ensuring efficient energy conversion and management.

2. Role in Energy Storage Systems

Ceramic capacitors are also employed in energy storage systems, helping to manage power flow and improve overall efficiency.

B. Wind Energy Systems

In wind energy systems, ceramic capacitors are used in control systems and energy management.

1. Applications in Control Systems

Ceramic capacitors help stabilize voltage levels and filter signals in control systems, ensuring reliable operation of wind turbines.

2. Importance in Energy Management

In energy management, ceramic capacitors play a crucial role in maintaining stable operation and improving overall efficiency.

IX. Conclusion

In summary, ceramic capacitors are integral to a wide range of applications across various industries. Their stability, reliability, and versatility make them essential components in consumer electronics, automotive systems, industrial applications, telecommunications, medical devices, and renewable energy systems. As technology continues to evolve, the demand for advanced ceramic capacitors will likely increase, driving innovation and development in this critical field. The future of ceramic capacitor technology holds promise, with potential advancements in materials and design that could further enhance their performance and applicability. Ultimately, ceramic capacitors will continue to play a significant role in shaping the future of modern electronics and various industries.