The latest specifications of the integrated circuit industrial park

The Latest Specifications of the Integrated Circuit Industrial Park

I. Introduction

In the rapidly evolving landscape of technology, Integrated Circuit (IC) Industrial Parks have emerged as pivotal hubs for innovation and production. These specialized zones are designed to foster the development and manufacturing of integrated circuits, which are essential components in virtually all electronic devices. As the demand for advanced electronics continues to surge, understanding the specifications and developments within IC Industrial Parks becomes crucial for stakeholders in the industry.

This blog post aims to provide an overview of the latest specifications and developments in IC Industrial Parks, highlighting their significance in the global economy and the technological advancements shaping their future.

II. Overview of Integrated Circuits

A. Definition and Function of Integrated Circuits

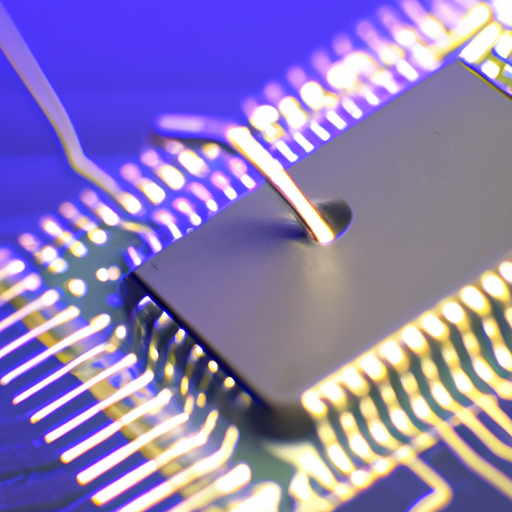

Integrated circuits are miniature electronic circuits that combine multiple components, such as transistors, resistors, and capacitors, onto a single semiconductor chip. They serve as the backbone of modern electronics, powering everything from smartphones to computers and automotive systems. The efficiency and compactness of ICs have revolutionized the electronics industry, enabling the development of smaller, faster, and more powerful devices.

B. Historical Context and Evolution of IC Technology

The journey of integrated circuits began in the late 1950s, with the invention of the first IC by Jack Kilby and Robert Noyce. Over the decades, advancements in semiconductor technology have led to the miniaturization of components and the ability to pack billions of transistors onto a single chip. This evolution has been driven by Moore's Law, which predicts that the number of transistors on a chip will double approximately every two years, leading to exponential growth in computing power.

C. Current Trends in IC Design and Manufacturing

Today, the IC industry is witnessing several trends, including the shift towards system-on-chip (SoC) designs, increased focus on energy efficiency, and the integration of artificial intelligence (AI) capabilities. Additionally, the rise of 5G technology and the Internet of Things (IoT) is driving demand for more sophisticated ICs that can handle complex tasks and connectivity requirements.

III. Key Specifications of Integrated Circuit Industrial Parks

A. Location and Infrastructure

1. Geographic Considerations

The location of an IC Industrial Park is critical for its success. Proximity to major markets, research institutions, and suppliers can significantly enhance operational efficiency. Regions with established tech ecosystems, such as Silicon Valley in the USA and Hsinchu Science Park in Taiwan, have become hotspots for IC manufacturing due to their access to talent and resources.

2. Transportation and Logistics

Efficient transportation and logistics are essential for the timely delivery of raw materials and finished products. IC Industrial Parks are often strategically located near major transportation hubs, including airports, seaports, and highways, to facilitate the movement of goods.

3. Utility Services (Power, Water, etc.)

The manufacturing of integrated circuits requires substantial amounts of energy and water. Therefore, reliable utility services are a must. Parks are designed with robust infrastructure to ensure uninterrupted power supply and efficient water management systems.

B. Facility Design and Layout

1. Cleanroom Standards

Cleanrooms are critical in IC manufacturing, as they minimize contamination that can affect the performance of chips. The latest specifications dictate stringent cleanroom standards, including controlled temperature, humidity, and particulate levels.

2. Production Space Requirements

The layout of production facilities is designed to optimize workflow and minimize waste. This includes dedicated spaces for different stages of manufacturing, from wafer fabrication to assembly and testing.

3. Research and Development Facilities

Innovation is at the heart of IC Industrial Parks. Therefore, R&D facilities are integrated into the design to foster collaboration between engineers and researchers, enabling the development of next-generation technologies.

C. Technology and Equipment

1. Advanced Manufacturing Equipment

The latest IC Industrial Parks are equipped with cutting-edge manufacturing equipment, including photolithography machines, etchers, and deposition systems. These tools are essential for producing high-performance chips with intricate designs.

2. Automation and Robotics

Automation plays a crucial role in enhancing productivity and reducing human error in IC manufacturing. The integration of robotics in assembly lines allows for faster production cycles and improved precision.

3. Testing and Quality Assurance Technologies

Quality assurance is paramount in the IC industry. Advanced testing technologies, such as automated test equipment (ATE) and in-line inspection systems, are employed to ensure that every chip meets stringent performance standards.

IV. Environmental and Safety Standards

A. Compliance with Environmental Regulations

1. Waste Management Practices

IC manufacturing generates various waste products, including hazardous materials. Compliance with environmental regulations requires effective waste management practices, including recycling and safe disposal methods.

2. Emission Controls

To minimize the environmental impact, IC Industrial Parks implement emission control technologies that reduce air pollutants and greenhouse gas emissions during the manufacturing process.

B. Safety Protocols in IC Manufacturing

1. Worker Safety Measures

The safety of workers is a top priority in IC manufacturing. Parks adhere to strict safety protocols, including the use of personal protective equipment (PPE) and regular safety training programs.

2. Emergency Response Plans

Preparedness for emergencies, such as chemical spills or equipment failures, is essential. IC Industrial Parks develop comprehensive emergency response plans to ensure the safety of personnel and the surrounding community.

V. Economic and Workforce Considerations

A. Economic Impact of IC Industrial Parks

1. Job Creation and Economic Growth

IC Industrial Parks contribute significantly to local economies by creating jobs and attracting investments. The establishment of these parks often leads to the development of ancillary industries, further boosting economic growth.

2. Investment Opportunities

As the demand for integrated circuits continues to rise, IC Industrial Parks present lucrative investment opportunities for both domestic and international investors. The potential for high returns in this sector is driving increased interest from venture capitalists and corporations alike.

B. Workforce Development

1. Skills and Training Requirements

The complexity of IC manufacturing necessitates a skilled workforce. IC Industrial Parks often collaborate with educational institutions to develop training programs that equip workers with the necessary skills in semiconductor technology and manufacturing processes.

2. Partnerships with Educational Institutions

Partnerships with universities and technical colleges are essential for fostering innovation and ensuring a steady pipeline of talent. These collaborations often involve research initiatives, internships, and co-op programs that benefit both students and the industry.

VI. Case Studies of Successful IC Industrial Parks

A. Overview of Notable IC Industrial Parks Globally

1. Silicon Valley, USA

Silicon Valley is synonymous with technological innovation. Home to numerous IC companies, this region has established a robust ecosystem that supports research, development, and manufacturing.

2. Hsinchu Science Park, Taiwan

Hsinchu Science Park is a leading IC manufacturing hub in Asia, known for its concentration of semiconductor companies and research institutions. The park has played a crucial role in Taiwan's economic development and technological advancement.

3. Shenzhen, China

Shenzhen has rapidly transformed into a global technology powerhouse, with a thriving IC industry. The city's focus on innovation and entrepreneurship has attracted significant investment and talent.

B. Analysis of Best Practices and Lessons Learned

The success of these IC Industrial Parks can be attributed to several best practices, including fostering collaboration between industry and academia, investing in infrastructure, and prioritizing sustainability. These lessons can serve as a blueprint for the development of future IC Industrial Parks.

VII. Future Trends and Innovations in IC Industrial Parks

A. Emerging Technologies in IC Manufacturing

1. AI and Machine Learning Applications

The integration of AI and machine learning in IC manufacturing is revolutionizing the industry. These technologies enable predictive maintenance, process optimization, and enhanced quality control, leading to increased efficiency and reduced costs.

2. Quantum Computing and Its Implications

Quantum computing represents a paradigm shift in computing technology. As research progresses, IC Industrial Parks will need to adapt to the unique requirements of quantum chip manufacturing, which may involve new materials and fabrication techniques.

B. Sustainability Initiatives

1. Green Manufacturing Practices

Sustainability is becoming a key focus in IC manufacturing. Parks are adopting green manufacturing practices, such as energy-efficient processes and the use of renewable energy sources, to minimize their environmental footprint.

2. Circular Economy in IC Production

The concept of a circular economy is gaining traction in the IC industry. This approach emphasizes recycling and reusing materials, reducing waste, and promoting sustainable practices throughout the supply chain.

VIII. Conclusion

In conclusion, Integrated Circuit Industrial Parks play a vital role in the global economy, driving innovation and technological advancement. The latest specifications and developments in these parks reflect the industry's commitment to efficiency, sustainability, and workforce development. As we look to the future, stakeholders in the IC industry must continue to adapt to emerging trends and challenges, ensuring that these critical hubs remain at the forefront of technological progress.

IX. References

1. Academic Journals and Articles

2. Industry Reports and White Papers

3. Government and Regulatory Publications

This blog post serves as a comprehensive overview of the latest specifications of integrated circuit industrial parks, providing insights into their significance and the factors shaping their future. As the demand for integrated circuits continues to grow, these parks will remain essential to the advancement of technology and the global economy.