What are the latest manufacturing processes for integrated circuits in Hangzhou?

What are the Latest Manufacturing Processes for Integrated Circuits in Hangzhou?

I. Introduction

A. Overview of Integrated Circuits (ICs)

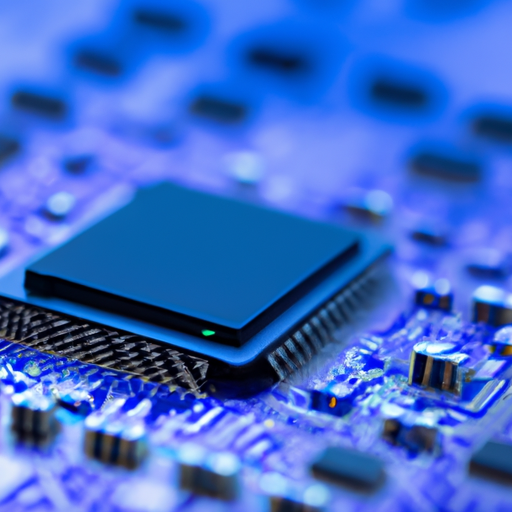

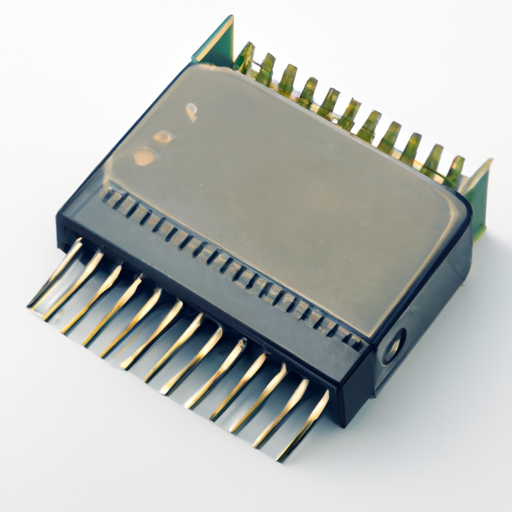

Integrated circuits (ICs) are the backbone of modern electronics, enabling the functionality of devices ranging from smartphones to sophisticated computing systems. An IC is a set of electronic circuits on a small chip of semiconductor material, typically silicon. The significance of ICs in contemporary technology cannot be overstated; they are essential for processing, storing, and transmitting information in virtually all electronic devices. The manufacturing processes that create these circuits are critical, as they determine the performance, efficiency, and cost-effectiveness of the final products.

B. Importance of Hangzhou in the IC Manufacturing Landscape

Hangzhou, a city renowned for its rich cultural heritage and rapid economic growth, has emerged as a significant player in the integrated circuit manufacturing sector. The city has witnessed substantial technological advancements, supported by government initiatives and investments. Key players in the Hangzhou IC industry include both established firms and innovative startups, contributing to the region's reputation as a hub for semiconductor manufacturing.

II. Historical Context of IC Manufacturing in Hangzhou

A. Evolution of the Semiconductor Industry in Hangzhou

The semiconductor industry in Hangzhou has evolved significantly over the past few decades. Early developments in the region were marked by the establishment of research institutions and the influx of talent from top universities. Government initiatives, such as funding for research and development, have played a crucial role in fostering growth. Key milestones include the establishment of semiconductor manufacturing facilities and partnerships with global technology firms.

B. Comparison with Other Major IC Manufacturing Hubs

While Hangzhou has made impressive strides, it faces competition from other major IC manufacturing hubs in China, such as Shenzhen and Shanghai, as well as global leaders like Taiwan and South Korea. Each region has its strengths, with Hangzhou focusing on innovation and research, while others may excel in mass production capabilities.

III. Current State of IC Manufacturing in Hangzhou

A. Overview of Major IC Manufacturing Companies

Hangzhou is home to several prominent IC manufacturing companies, including Hangzhou Silan Microelectronics and Zhejiang University’s research initiatives. These firms are at the forefront of developing cutting-edge technologies and products. Collaborations between academia and industry have fostered an environment of innovation, leading to the development of new manufacturing processes and products.

B. Infrastructure and Resources

The infrastructure supporting IC manufacturing in Hangzhou is robust, with state-of-the-art research and development facilities. The city boasts a skilled workforce, thanks in part to its educational institutions, which produce graduates in engineering and technology fields. This combination of resources positions Hangzhou as a competitive player in the global semiconductor market.

IV. Latest Manufacturing Processes for Integrated Circuits

A. Advanced Lithography Techniques

One of the most significant advancements in IC manufacturing is the development of advanced lithography techniques. Extreme Ultraviolet (EUV) lithography has revolutionized the way circuits are printed on silicon wafers, allowing for smaller features and increased density. This technology enables manufacturers to produce chips with higher performance and lower power consumption. Additionally, multi-patterning techniques are being employed to further push the limits of miniaturization, allowing for the creation of intricate circuit designs.

B. 3D IC and System-on-Chip (SoC) Technologies

The adoption of 3D IC and System-on-Chip (SoC) technologies is another trend shaping the future of IC manufacturing. 3D integration allows for stacking multiple layers of circuits, significantly improving performance and reducing the footprint of devices. SoCs, which integrate all components of a computer or other electronic system onto a single chip, are becoming increasingly popular due to their efficiency and compactness. These technologies are driving innovation in various applications, including mobile devices, IoT, and automotive systems.

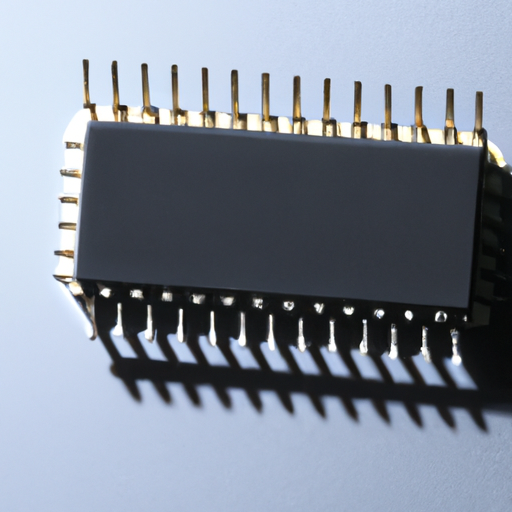

C. Advanced Packaging Technologies

Advanced packaging technologies are also transforming the IC manufacturing landscape. Fan-out wafer-level packaging (FOWLP) is gaining traction as it allows for a more efficient use of space and improved thermal performance. This method enables the integration of multiple chips into a single package, enhancing functionality while minimizing size. Additionally, chiplet architecture is emerging as a viable solution for creating modular ICs, allowing manufacturers to mix and match different components to meet specific performance requirements.

D. Automation and Smart Manufacturing

The integration of automation and smart manufacturing practices is reshaping the IC manufacturing process. The use of artificial intelligence (AI) and machine learning is streamlining production, improving quality control, and reducing waste. Industry 4.0 principles are being adopted, leading to more efficient and flexible manufacturing systems. These advancements not only enhance productivity but also enable manufacturers to respond quickly to market demands.

V. Challenges Facing IC Manufacturing in Hangzhou

A. Supply Chain Issues and Material Shortages

Despite the advancements, the IC manufacturing industry in Hangzhou faces several challenges. Supply chain disruptions and material shortages have become increasingly common, impacting production timelines and costs. The global semiconductor shortage has highlighted the vulnerabilities in the supply chain, prompting manufacturers to seek more resilient sourcing strategies.

B. Competition from Other Regions and Countries

Hangzhou's IC industry also contends with fierce competition from other regions and countries. As global demand for semiconductors continues to rise, other manufacturing hubs are ramping up their capabilities, making it essential for Hangzhou to innovate and differentiate itself in the market.

C. Regulatory and Environmental Considerations

Regulatory and environmental considerations are becoming more prominent in the IC manufacturing sector. Manufacturers must navigate complex regulations related to environmental impact and sustainability, which can affect production processes and costs. Embracing green manufacturing practices is not only a regulatory requirement but also a market expectation.

VI. Future Trends in IC Manufacturing in Hangzhou

A. Emerging Technologies and Innovations

Looking ahead, several emerging technologies and innovations are poised to shape the future of IC manufacturing in Hangzhou. Quantum computing, for instance, holds the potential to revolutionize the industry by enabling unprecedented processing power. As research in this area progresses, it could lead to new types of integrated circuits that outperform traditional silicon-based chips.

B. Sustainability and Green Manufacturing Practices

Sustainability is becoming a critical focus for the IC industry. Manufacturers are increasingly adopting green practices to minimize their environmental footprint. This includes optimizing energy consumption, reducing waste, and utilizing eco-friendly materials. The push for sustainability is not only driven by regulatory requirements but also by consumer demand for environmentally responsible products.

C. Predictions for Growth

The IC industry in Hangzhou is expected to experience significant growth in the coming years. Market forecasts indicate increasing demand for semiconductors across various sectors, including automotive, telecommunications, and consumer electronics. Investment opportunities are likely to arise as companies seek to expand their capabilities and explore new technologies. Furthermore, the potential for international collaboration and partnerships could enhance Hangzhou's position in the global semiconductor landscape.

VII. Conclusion

In summary, Hangzhou is emerging as a vital player in the integrated circuit manufacturing landscape, driven by technological advancements and a supportive ecosystem. The city’s historical context, current state, and future trends highlight its significance in the global semiconductor industry. As Hangzhou continues to innovate and adapt to challenges, it is well-positioned to contribute to the future of integrated circuits, ensuring its place in the ever-evolving world of technology.

VIII. References

- Academic journals and articles on semiconductor manufacturing

- Industry reports and market analyses from leading research firms

- Government publications and statistics on the IC industry in Hangzhou

This blog post provides a comprehensive overview of the latest manufacturing processes for integrated circuits in Hangzhou, emphasizing the city's role in the global semiconductor landscape. The discussion encompasses historical context, current advancements, challenges, and future trends, offering readers a well-rounded understanding of the topic.