Mainstream automotive capacitor product series parameters

Mainstream Automotive Capacitor Product Series Parameters

I. Introduction

In the rapidly evolving automotive industry, capacitors play a crucial role in ensuring the reliability and efficiency of various electronic systems. Automotive capacitors are specialized components designed to store and release electrical energy, providing essential functions in modern vehicles. As vehicles become increasingly reliant on electronic systems for everything from engine management to infotainment, understanding the parameters and characteristics of automotive capacitors is vital for engineers, manufacturers, and enthusiasts alike. This blog post will explore the different types of automotive capacitors, their key parameters, applications, and the latest trends in capacitor technology.

II. Types of Automotive Capacitors

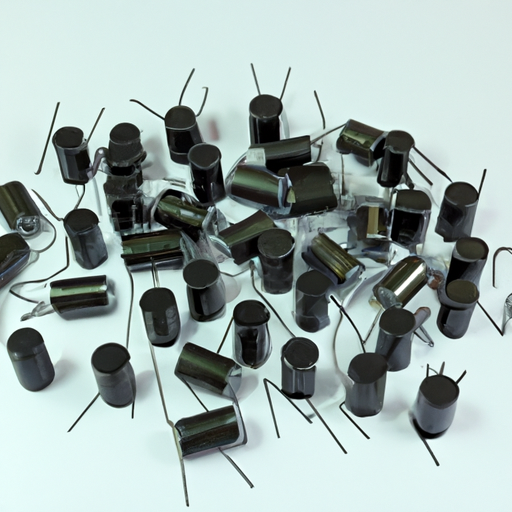

A. Electrolytic Capacitors

Electrolytic capacitors are widely used in automotive applications due to their high capacitance values and relatively low cost. These capacitors are polarized, meaning they have a positive and negative terminal, which makes them suitable for DC applications.

**Characteristics:** Electrolytic capacitors typically have capacitance values ranging from microfarads (µF) to millifarads (mF) and are known for their high energy density. However, they have a limited voltage rating and can be sensitive to temperature variations.

**Applications in Automotive Systems:** Commonly found in power supply circuits, electrolytic capacitors are essential for smoothing out voltage fluctuations and providing stable power to electronic control units (ECUs) in vehicles.

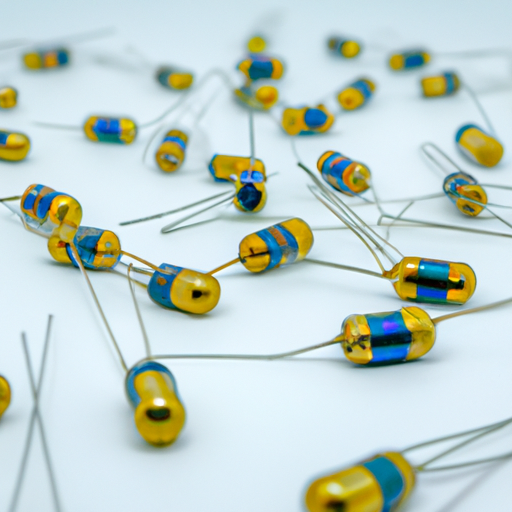

B. Ceramic Capacitors

Ceramic capacitors are non-polarized components that are known for their reliability and stability. They are made from ceramic materials and are available in various capacitance values.

**Characteristics:** These capacitors have low equivalent series resistance (ESR) and can operate over a wide temperature range. They are available in both multilayer and single-layer configurations.

**Applications in Automotive Systems:** Ceramic capacitors are often used in high-frequency applications, such as filtering and decoupling in communication systems, making them ideal for automotive sensors and infotainment systems.

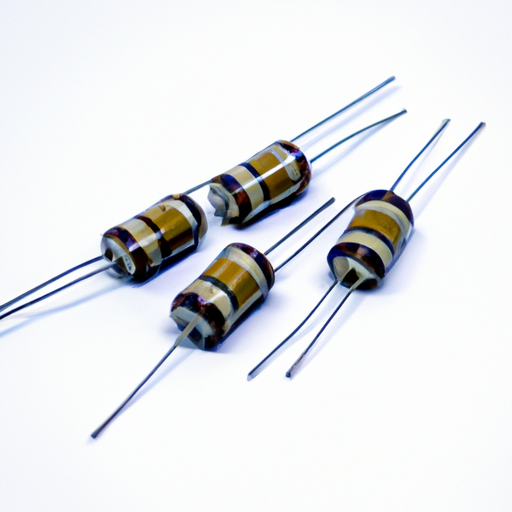

C. Film Capacitors

Film capacitors are constructed using thin plastic films as the dielectric material. They are known for their excellent stability and low loss characteristics.

**Characteristics:** These capacitors have a wide capacitance range and can handle high voltages. They are non-polarized and exhibit low ESR, making them suitable for various applications.

**Applications in Automotive Systems:** Film capacitors are commonly used in power electronics, such as inverters and converters, particularly in hybrid and electric vehicles where efficiency is paramount.

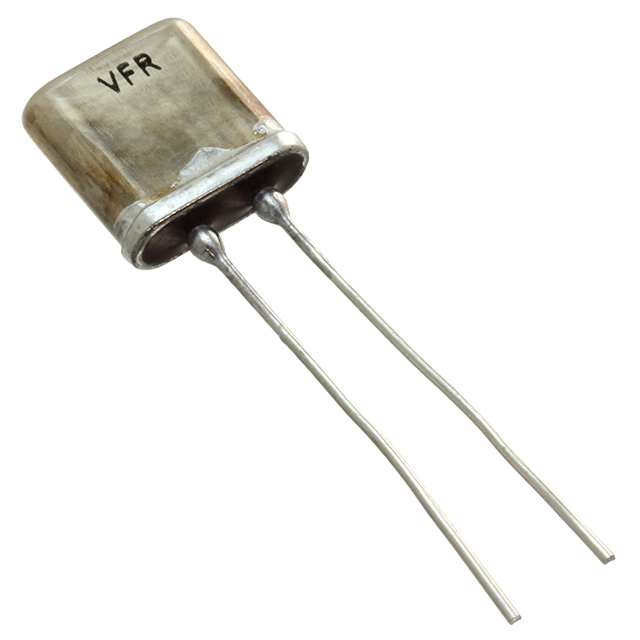

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance values in a small package. They are made from tantalum metal and are also polarized.

**Characteristics:** These capacitors have a high energy density and excellent stability, but they can be more expensive than other types. They are also sensitive to voltage spikes.

**Applications in Automotive Systems:** Tantalum capacitors are often used in critical applications, such as in power management circuits and advanced driver-assistance systems (ADAS), where reliability is essential.

III. Key Parameters of Automotive Capacitors

A. Capacitance Value

**Definition and Measurement:** Capacitance is the ability of a capacitor to store electrical energy, measured in farads (F). In automotive applications, capacitance values typically range from picofarads (pF) to microfarads (µF).

**Importance in Automotive Circuits:** The capacitance value directly affects the performance of electronic circuits, influencing how well they can filter noise, stabilize voltage, and store energy.

B. Voltage Rating

**Definition and Significance:** The voltage rating indicates the maximum voltage a capacitor can handle without failing. Exceeding this rating can lead to catastrophic failure.

**Common Voltage Ratings in Automotive Applications:** Automotive capacitors typically have voltage ratings ranging from 16V to 100V, depending on their application. For example, power supply capacitors may require higher ratings due to voltage spikes.

C. Temperature Coefficient

**Explanation of Temperature Effects:** The temperature coefficient indicates how a capacitor's capacitance changes with temperature. This is crucial in automotive environments, where temperatures can vary significantly.

**Importance in Automotive Environments:** Capacitors with a low temperature coefficient are preferred in automotive applications to ensure consistent performance across a wide temperature range.

D. Equivalent Series Resistance (ESR)

**Definition and Impact on Performance:** ESR is the internal resistance of a capacitor that affects its efficiency and heat generation. Lower ESR values are desirable for better performance.

**Typical ESR Values for Automotive Capacitors:** Automotive capacitors typically have ESR values ranging from a few milliohms to several ohms, depending on the type and application.

E. Lifetime and Reliability

**Factors Affecting Lifespan:** The lifespan of a capacitor can be influenced by factors such as temperature, voltage stress, and ripple current.

**Testing Standards and Reliability Metrics:** Automotive capacitors are often subjected to rigorous testing standards, such as AEC-Q200, to ensure their reliability in harsh automotive environments.

IV. Automotive Capacitor Applications

A. Power Supply Filtering

**Role in Stabilizing Voltage:** Capacitors are essential for filtering out voltage spikes and smoothing out fluctuations in power supply circuits.

**Examples of Use in Automotive Electronics:** They are commonly used in ECUs, power distribution modules, and battery management systems to ensure stable operation.

B. Energy Storage

**Capacitors in Hybrid and Electric Vehicles:** In hybrid and electric vehicles, capacitors are used for energy storage, providing quick bursts of power when needed.

**Benefits of Energy Storage in Automotive Systems:** This capability enhances performance, improves fuel efficiency, and extends the lifespan of batteries by reducing the load during peak demand.

C. Signal Coupling and Decoupling

**Importance in Communication Systems:** Capacitors are used to couple and decouple signals in automotive communication systems, ensuring clear and reliable data transmission.

**Examples of Applications in Automotive Sensors:** They are found in various sensors, including those used for engine management and safety systems, where accurate signal processing is critical.

D. Noise Suppression

**Role in Reducing Electromagnetic Interference (EMI):** Capacitors help suppress noise and EMI, which can interfere with the operation of sensitive electronic components.

**Applications in Automotive Audio Systems:** In automotive audio systems, capacitors are used to filter out unwanted noise, ensuring high-quality sound reproduction.

V. Trends and Innovations in Automotive Capacitor Technology

A. Miniaturization and Integration

**Impact on Design and Performance:** As automotive systems become more compact, the demand for smaller capacitors that can deliver high performance has increased.

**Examples of Compact Capacitor Solutions:** Manufacturers are developing miniaturized capacitors that can fit into tight spaces without compromising performance.

B. Advanced Materials

**Development of New Dielectric Materials:** Innovations in dielectric materials are leading to capacitors with improved performance characteristics, such as higher capacitance and lower ESR.

**Benefits for Automotive Applications:** These advancements enhance the reliability and efficiency of automotive systems, particularly in high-performance applications.

C. Smart Capacitors

**Introduction to Smart Technology in Capacitors:** The integration of smart technology into capacitors allows for real-time monitoring and diagnostics.

**Potential Applications in Future Automotive Systems:** Smart capacitors could play a significant role in the development of autonomous vehicles, providing critical data for system optimization and safety.

VI. Conclusion

In summary, automotive capacitors are essential components that contribute to the performance, reliability, and efficiency of modern vehicles. Understanding the various types of capacitors, their key parameters, and applications is crucial for anyone involved in the automotive industry. As technology continues to advance, the future of automotive capacitors looks promising, with innovations in materials and smart technology paving the way for even more efficient and reliable automotive systems. By staying informed about these developments, engineers and manufacturers can better design and implement capacitor solutions that meet the demands of the evolving automotive landscape.

VII. References

1. AEC-Q200: Stress Test Qualification for Passive Components.

2. "Capacitor Technology in Automotive Applications," Journal of Automotive Engineering.

3. Manufacturer specifications and datasheets for automotive capacitors.

4. Industry reports on trends in automotive electronics and capacitor technology.

This blog post provides a comprehensive overview of automotive capacitors, their types, parameters, applications, and emerging trends, making it a valuable resource for anyone interested in the field.