How to choose a spot capacitor factory?

How to Choose a Spot Capacitor Factory

Introduction

Capacitors are essential components in electronic devices, playing a crucial role in energy storage, filtering, and signal processing. From smartphones to industrial machinery, capacitors are integral to the functionality and efficiency of countless applications. Given their importance, selecting the right capacitor factory is a critical decision for manufacturers and engineers alike. This article aims to guide you through the process of choosing a reliable spot capacitor factory, ensuring that you make an informed choice that meets your quality, performance, and cost requirements.

1. Understanding Capacitors

1.1 Definition and Function of Capacitors

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material, known as a dielectric. When voltage is applied, an electric field forms between the plates, allowing the capacitor to store energy. Capacitors are used in various applications, including energy storage, power conditioning, signal coupling, and decoupling.

1.2 Types of Capacitors

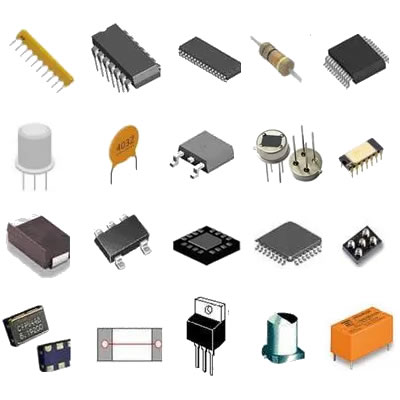

Capacitors come in various types, each suited for specific applications:

1.2.1 Ceramic Capacitors

Ceramic capacitors are widely used due to their small size, low cost, and stability. They are ideal for high-frequency applications and are commonly found in RF circuits and decoupling applications.

1.2.2 Electrolytic Capacitors

Electrolytic capacitors are polarized components that offer high capacitance values in a compact form. They are often used in power supply circuits and energy storage applications.

1.2.3 Film Capacitors

Film capacitors are known for their reliability and stability. They are used in applications requiring low losses and high voltage ratings, such as audio equipment and power electronics.

1.2.4 Tantalum Capacitors

Tantalum capacitors are known for their high capacitance and small size. They are often used in portable electronics and applications where space is limited.

1.3 Applications of Capacitors in Various Industries

Capacitors find applications across multiple industries, including consumer electronics, automotive, telecommunications, and industrial automation. Their versatility makes them indispensable in modern electronic design.

2. Importance of Choosing the Right Factory

2.1 Quality Assurance

The quality of capacitors directly impacts the performance and reliability of electronic devices. Choosing a factory with stringent quality assurance processes ensures that the capacitors meet industry standards and perform as expected.

2.2 Cost Efficiency

Selecting the right factory can lead to significant cost savings. A factory that offers competitive pricing without compromising quality can help you maintain your budget while ensuring product reliability.

2.3 Reliability and Performance

Capacitors must perform consistently under various conditions. A reputable factory will have a track record of producing reliable components that meet or exceed performance specifications.

2.4 Compliance with Industry Standards

Compliance with industry standards, such as ISO and RoHS, is crucial for ensuring that the capacitors are safe and environmentally friendly. A factory that adheres to these standards demonstrates a commitment to quality and responsibility.

3. Key Factors to Consider When Choosing a Spot Capacitor Factory

3.1 Manufacturing Capabilities

3.1.1 Technology and Equipment

Evaluate the factory's technology and equipment. Advanced manufacturing processes and state-of-the-art machinery can significantly enhance product quality and consistency.

3.1.2 Production Capacity

Consider the factory's production capacity to ensure they can meet your demand. A factory with sufficient capacity can provide timely deliveries and accommodate future growth.

3.2 Quality Control Processes

3.2.1 Testing and Certification

Inquire about the factory's testing and certification processes. Rigorous testing ensures that the capacitors meet performance specifications and industry standards.

3.2.2 ISO Standards and Compliance

Check if the factory is ISO certified. ISO standards indicate a commitment to quality management and continuous improvement.

3.3 Experience and Reputation

3.3.1 Industry Experience

A factory with extensive industry experience is likely to have a better understanding of market demands and challenges. Look for manufacturers with a proven track record in capacitor production.

3.3.2 Customer Reviews and Testimonials

Research customer reviews and testimonials to gauge the factory's reputation. Positive feedback from other clients can provide insights into the factory's reliability and service quality.

3.4 Location and Logistics

3.4.1 Proximity to Supply Chains

Consider the factory's location in relation to your supply chains. A factory located near suppliers can reduce lead times and transportation costs.

3.4.2 Shipping and Delivery Times

Evaluate the factory's shipping and delivery capabilities. Timely delivery is crucial for maintaining production schedules and meeting customer demands.

3.5 Customer Support and Communication

3.5.1 Responsiveness

Effective communication is vital when working with a factory. Assess their responsiveness to inquiries and requests for information.

3.5.2 Technical Support

A factory that offers technical support can assist you in troubleshooting issues and optimizing capacitor performance in your applications.

4. Evaluating Potential Factories

4.1 Conducting Research

4.1.1 Online Resources and Directories

Utilize online resources and directories to identify potential capacitor factories. Websites like ThomasNet and Alibaba can provide valuable information about manufacturers.

4.1.2 Trade Shows and Industry Events

Attending trade shows and industry events can help you connect with manufacturers and gain insights into the latest technologies and trends in capacitor production.

4.2 Visiting Factories

4.2.1 Importance of On-Site Visits

If possible, visit the factories you are considering. On-site visits allow you to assess the manufacturing processes, quality control measures, and overall working environment.

4.2.2 What to Look for During a Visit

During your visit, pay attention to the cleanliness of the facility, the condition of the equipment, and the professionalism of the staff. These factors can indicate the factory's commitment to quality.

4.3 Requesting Samples

4.3.1 Importance of Testing Samples

Request samples of the capacitors you intend to purchase. Testing samples allows you to evaluate their performance and suitability for your applications.

4.3.2 Analyzing Sample Performance

Conduct thorough testing of the samples to ensure they meet your specifications. Analyze parameters such as capacitance, voltage rating, and temperature stability.

5. Cost Considerations

5.1 Understanding Pricing Structures

Familiarize yourself with the factory's pricing structures. Understanding how pricing is determined can help you make informed decisions and avoid unexpected costs.

5.2 Balancing Cost and Quality

While cost is an important factor, it should not come at the expense of quality. Strive to find a balance between cost and quality to ensure reliable performance.

5.3 Negotiating Terms and Conditions

Don’t hesitate to negotiate terms and conditions with the factory. Clear agreements on pricing, delivery schedules, and quality expectations can prevent misunderstandings later on.

6. Building a Long-Term Relationship

6.1 Importance of Partnership

Establishing a long-term partnership with a capacitor factory can lead to better pricing, improved communication, and enhanced collaboration on product development.

6.2 Communication and Feedback

Maintain open lines of communication with the factory. Providing feedback on product performance and service can help foster a positive working relationship.

6.3 Continuous Improvement and Innovation

Encourage the factory to pursue continuous improvement and innovation. A factory that invests in research and development can offer you cutting-edge solutions and products.

Conclusion

Choosing the right spot capacitor factory is a critical decision that can significantly impact the quality and reliability of your electronic products. By understanding the various types of capacitors, evaluating potential factories based on key factors, and building a long-term relationship, you can ensure that you select a manufacturer that meets your needs. Take the time to thoroughly evaluate your options, and you will be well on your way to sourcing high-quality capacitors that enhance the performance of your electronic devices.

References

- "Capacitors: Basics and Applications" - Electronics Tutorials

- "Understanding Capacitor Types" - All About Circuits

- "ISO Standards for Capacitor Manufacturing" - ISO.org

- "The Importance of Quality Control in Manufacturing" - Quality Digest