What are the product standards for capacitors in series?

What are the Product Standards for Capacitors in Series?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving various roles such as energy storage, filtering, and timing. They store electrical energy in an electric field, allowing them to release it when needed. Capacitors can be connected in different configurations, with series connections being one of the most common. Understanding the product standards for capacitors in series is crucial for ensuring their reliability and performance in electronic applications. This article aims to explore these standards, their importance, and the implications for manufacturers and engineers.

II. Understanding Capacitors in Series

A. Basic Principles of Capacitors

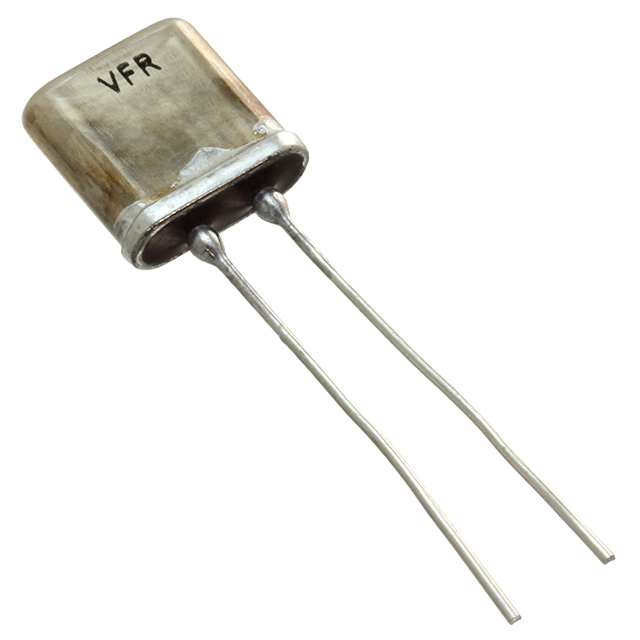

1. **Capacitance and Its Units**: Capacitance is the ability of a capacitor to store charge per unit voltage, measured in farads (F). In practical applications, capacitors are often rated in microfarads (µF), nanofarads (nF), or picofarads (pF).

2. **Functionality of Capacitors in Circuits**: Capacitors play a vital role in smoothing out voltage fluctuations, filtering signals, and providing timing elements in oscillators. Their ability to store and release energy makes them indispensable in various electronic devices.

B. Series Configuration of Capacitors

1. **How Capacitors Behave in Series**: When capacitors are connected in series, the total capacitance decreases. This is because the charge stored on each capacitor is the same, but the voltage across each capacitor adds up.

2. **Formula for Total Capacitance in Series**: The formula for calculating the total capacitance (C_total) of capacitors in series is given by:

\[

\frac{1}{C_{total}} = \frac{1}{C_1} + \frac{1}{C_2} + \frac{1}{C_3} + \ldots

\]

This means that the total capacitance is always less than the smallest individual capacitor in the series.

C. Applications of Capacitors in Series

1. **Filtering and Timing Applications**: Capacitors in series are often used in filter circuits to block certain frequencies while allowing others to pass. They are also used in timing circuits, where the charge and discharge times are critical.

2. **Voltage Division and Energy Storage**: In applications requiring voltage division, capacitors in series can help achieve the desired voltage levels. They also play a role in energy storage systems, where multiple capacitors are used to manage energy flow.

III. Product Standards for Capacitors

A. Overview of Product Standards

1. **Definition and Purpose of Product Standards**: Product standards are established guidelines that ensure the safety, reliability, and performance of electronic components. They provide a framework for manufacturers to design and test their products.

2. **Importance of Compliance with Standards**: Compliance with product standards is essential for manufacturers to ensure that their capacitors meet industry requirements and can be safely used in various applications.

B. Key Organizations and Standards

1. **International Electrotechnical Commission (IEC)**: The IEC develops international standards for electrical and electronic technologies, including capacitors.

2. **Institute of Electrical and Electronics Engineers (IEEE)**: IEEE standards focus on electrical and electronic engineering practices, providing guidelines for capacitor performance and testing.

3. **Underwriters Laboratories (UL)**: UL standards ensure the safety of electrical components, including capacitors, by testing for fire and electrical hazards.

4. **American National Standards Institute (ANSI)**: ANSI oversees the development of consensus standards for various industries, including electronics.

C. Specific Standards for Capacitors

1. **IEC 60384**: This standard covers fixed capacitors for use in electronic equipment, specifying performance requirements and testing methods.

2. **IEC 61071**: This standard pertains to capacitors used in power electronics, focusing on their performance under high voltage and temperature conditions.

3. **MIL-PRF-39014**: This military specification outlines the requirements for capacitors used in military applications, ensuring high reliability and performance.

4. **Other Relevant Standards**: Additional standards may apply depending on the specific application and environment in which the capacitors are used.

IV. Key Parameters and Testing Methods

A. Electrical Parameters

1. **Capacitance Tolerance**: This parameter indicates the allowable deviation from the nominal capacitance value, which is crucial for ensuring circuit performance.

2. **Voltage Rating**: The voltage rating specifies the maximum voltage a capacitor can handle without failure. Exceeding this rating can lead to catastrophic failure.

3. **Equivalent Series Resistance (ESR)**: ESR is a measure of the internal resistance of a capacitor, affecting its efficiency and heat generation during operation.

4. **Temperature Coefficient**: This parameter indicates how capacitance changes with temperature, which is vital for applications in varying environmental conditions.

B. Mechanical Parameters

1. **Size and Form Factor**: The physical dimensions and shape of capacitors are important for fitting them into circuit designs.

2. **Mounting Types**: Capacitors can be surface-mounted or through-hole, and the choice depends on the application and design requirements.

C. Testing Methods

1. **Capacitance Measurement**: Accurate measurement of capacitance is essential for ensuring that capacitors meet their specified values.

2. **Insulation Resistance Testing**: This test checks the integrity of the capacitor's insulation, ensuring it can withstand the operating voltage without leakage.

3. **Endurance Testing**: Capacitors undergo endurance testing to evaluate their performance over extended periods under specified conditions.

4. **Life Testing**: Life testing assesses the longevity of capacitors, simulating real-world operating conditions to predict their lifespan.

V. Quality Assurance and Reliability

A. Importance of Quality Assurance in Capacitor Manufacturing

Quality assurance is critical in capacitor manufacturing to ensure that products meet established standards and perform reliably in their intended applications.

B. Reliability Testing Standards

1. **Accelerated Life Testing**: This method subjects capacitors to extreme conditions to simulate long-term use, helping to identify potential failures.

2. **Environmental Testing**: Capacitors are tested under various environmental conditions, such as temperature and humidity, to ensure they can operate reliably in different settings.

C. Role of Certifications in Ensuring Quality

1. **ISO Certifications**: ISO certifications indicate that a manufacturer adheres to international quality management standards, ensuring consistent product quality.

2. **RoHS Compliance**: Compliance with the Restriction of Hazardous Substances (RoHS) directive ensures that capacitors are free from harmful materials, promoting environmental safety.

VI. Challenges and Considerations

A. Common Challenges in Capacitor Design and Manufacturing

1. **Variability in Materials**: The choice of materials can significantly impact capacitor performance, and variability can lead to inconsistencies.

2. **Environmental Factors**: Capacitors must be designed to withstand various environmental conditions, which can complicate the manufacturing process.

B. Considerations for Selecting Capacitors in Series

1. **Application-Specific Requirements**: Engineers must consider the specific requirements of their applications, such as voltage, capacitance, and size.

2. **Balancing Performance and Cost**: Selecting the right capacitors involves balancing performance characteristics with budget constraints, ensuring that the final product meets both technical and financial goals.

VII. Conclusion

In conclusion, understanding the product standards for capacitors in series is essential for ensuring their reliability and performance in electronic applications. Compliance with established standards not only guarantees safety but also enhances the overall quality of electronic devices. As technology continues to evolve, so too will the standards governing capacitor design and manufacturing. Manufacturers and engineers must stay informed about these changes to ensure that their products meet the highest standards of quality and reliability.

VIII. References

- International Electrotechnical Commission (IEC) Standards

- Institute of Electrical and Electronics Engineers (IEEE) Standards

- Underwriters Laboratories (UL) Standards

- American National Standards Institute (ANSI) Standards

- MIL-PRF-39014 Military Specifications

- ISO Quality Management Standards

- RoHS Directive Compliance Guidelines

This comprehensive overview of product standards for capacitors in series highlights the importance of adhering to established guidelines to ensure the safety, reliability, and performance of these critical electronic components.