What product types do high-voltage capacitors include?

What Product Types Do High-Voltage Capacitors Include?

I. Introduction

High-voltage capacitors are essential components in various electrical and electronic systems, playing a critical role in energy storage, power delivery, and circuit protection. Defined as capacitors that can operate at voltages significantly higher than standard capacitors, these components are designed to handle the demands of high-voltage applications. Their importance spans across multiple industries, including power electronics, telecommunications, industrial equipment, and medical devices. This article aims to provide an overview of the different types of high-voltage capacitors, their characteristics, and their applications.

II. Understanding High-Voltage Capacitors

A. Explanation of Voltage Ratings and Classifications

High-voltage capacitors are classified based on their voltage ratings, which can range from several hundred volts to several kilovolts. The classification is crucial as it determines the capacitor's suitability for specific applications. Voltage ratings are typically defined by the maximum voltage the capacitor can withstand without breaking down.

B. Key Characteristics of High-Voltage Capacitors

1. **Capacitance Values**: High-voltage capacitors come in various capacitance values, which are measured in farads (F). The capacitance value indicates the capacitor's ability to store electrical energy. Depending on the application, these values can range from picofarads (pF) to microfarads (µF).

2. **Dielectric Materials**: The dielectric material used in high-voltage capacitors significantly influences their performance. Common dielectric materials include ceramic, polyester, polypropylene, and tantalum. Each material has unique properties that affect the capacitor's stability, efficiency, and temperature tolerance.

3. **Temperature and Voltage Stability**: High-voltage capacitors must maintain their performance across a range of temperatures and voltages. Stability is crucial for ensuring reliability in demanding environments, such as industrial settings or high-frequency applications.

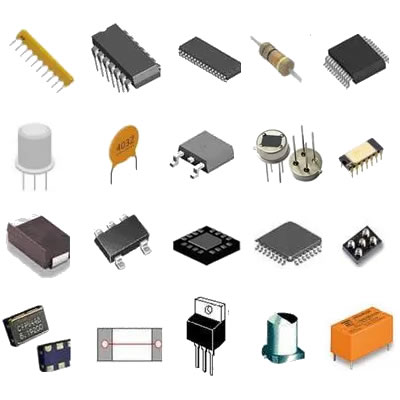

III. Types of High-Voltage Capacitors

A. Ceramic Capacitors

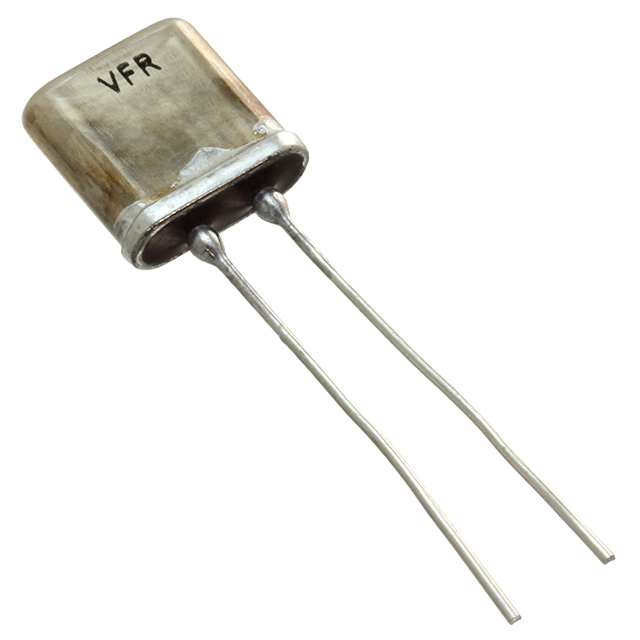

1. **Description and Construction**: Ceramic capacitors are made from ceramic materials that serve as the dielectric. They are typically small, lightweight, and can handle high voltages, making them suitable for various applications.

2. **Applications and Advantages**: These capacitors are widely used in RF applications, power supply circuits, and snubber circuits due to their stability and reliability. Their ability to operate at high temperatures and voltages makes them a popular choice in high-voltage applications.

B. Film Capacitors

1. **Types of Film Capacitors**: Film capacitors are made using thin plastic films as the dielectric. Common types include polyester, polypropylene, and polycarbonate capacitors. Each type has distinct characteristics that make it suitable for specific applications.

2. **Benefits and Typical Uses**: Film capacitors are known for their low loss, high insulation resistance, and excellent stability. They are commonly used in power electronics, audio equipment, and motor drives, where reliability and performance are critical.

C. Electrolytic Capacitors

1. **Characteristics and Construction**: Electrolytic capacitors use an electrolyte as one of their plates, allowing for higher capacitance values in a smaller package. They are polarized, meaning they must be connected in the correct direction in a circuit.

2. **Applications in High-Voltage Scenarios**: These capacitors are often used in power supply circuits, energy storage systems, and audio applications. Their ability to handle high capacitance values makes them suitable for applications requiring significant energy storage.

D. Tantalum Capacitors

1. **Unique Properties and Construction**: Tantalum capacitors are made from tantalum metal and are known for their high capacitance-to-volume ratio. They are also stable and reliable, making them suitable for high-voltage applications.

2. **Use Cases in High-Voltage Applications**: Tantalum capacitors are commonly used in military and aerospace applications, as well as in medical devices, where reliability and performance are paramount.

E. Supercapacitors

1. **Definition and Working Principle**: Supercapacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries. They store energy through electrostatic charge rather than chemical reactions.

2. **Applications in Energy Storage and Power Delivery**: Supercapacitors are used in applications requiring rapid charge and discharge cycles, such as regenerative braking systems in electric vehicles and backup power systems in telecommunications.

IV. Specialized High-Voltage Capacitors

A. Power Factor Correction Capacitors

1. **Role in Electrical Systems**: Power factor correction capacitors are used to improve the power factor in electrical systems, reducing energy losses and improving efficiency.

2. **Types and Applications**: These capacitors can be fixed or automatic and are commonly used in industrial settings to optimize the performance of motors and other inductive loads.

B. Snubber Capacitors

1. **Purpose in Circuit Protection**: Snubber capacitors are used to protect circuits from voltage spikes and transients. They help to absorb excess energy and prevent damage to sensitive components.

2. **Design Considerations**: The design of snubber circuits must consider the specific application, including the voltage and current ratings, to ensure effective protection.

C. Pulse Capacitors

1. **Characteristics and Applications in Pulsed Power Systems**: Pulse capacitors are designed to handle high-energy pulses and are used in applications such as laser systems, particle accelerators, and pulsed power systems.

2. **Importance in High-Energy Applications**: These capacitors must be able to withstand rapid charge and discharge cycles, making them critical in applications where high energy is delivered in short bursts.

V. Applications of High-Voltage Capacitors

A. Power Electronics

1. **Role in Inverters and Converters**: High-voltage capacitors are essential in power electronics, where they help to smooth out voltage fluctuations and provide stable power delivery in inverters and converters.

2. **Importance in Renewable Energy Systems**: In renewable energy systems, such as solar and wind, high-voltage capacitors play a crucial role in energy storage and management, ensuring efficient energy conversion and distribution.

B. Industrial Equipment

1. **Use in Motors and Drives**: High-voltage capacitors are commonly used in industrial motors and drives, where they help to improve efficiency and performance.

2. **Applications in Manufacturing Processes**: In manufacturing, these capacitors are used in various applications, including welding, induction heating, and other processes requiring high power.

C. Telecommunications

1. **Role in Signal Processing and Transmission**: High-voltage capacitors are used in telecommunications equipment to filter signals and ensure reliable transmission.

2. **Importance in High-Frequency Applications**: In high-frequency applications, these capacitors help to maintain signal integrity and reduce noise, which is critical for effective communication.

D. Medical Equipment

1. **Use in Imaging and Diagnostic Devices**: High-voltage capacitors are essential in medical imaging devices, such as MRI and CT scanners, where they help to generate the high voltages required for imaging.

2. **Importance in Life-Saving Technologies**: In life-saving technologies, such as defibrillators, high-voltage capacitors are crucial for delivering the necessary energy to restore normal heart rhythm.

VI. Conclusion

High-voltage capacitors are vital components in a wide range of applications, from power electronics to medical devices. Their ability to handle high voltages and store significant amounts of energy makes them indispensable in modern technology. This article has explored the various types of high-voltage capacitors, including ceramic, film, electrolytic, tantalum, and supercapacitors, as well as specialized capacitors like power factor correction and snubber capacitors. As technology continues to evolve, the demand for high-voltage capacitors will likely grow, leading to innovations and advancements in capacitor technology.

VII. References

A. Suggested readings and resources for further exploration include industry publications, technical papers, and manufacturer datasheets on high-voltage capacitors.

B. Industry standards and guidelines related to high-voltage capacitors can be found through organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC).