What are the equipment procurement models of the latest capacitor group?

Equipment Procurement Models of the Latest Capacitor Group

I. Introduction

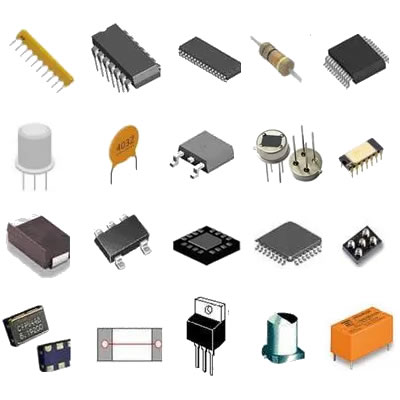

Capacitor groups are essential components in various electronic devices, playing a critical role in energy storage, filtering, and power management. As technology advances, the demand for high-performance capacitors has surged, necessitating efficient equipment procurement strategies within the capacitor industry. This blog post explores the latest equipment procurement models employed by capacitor manufacturers, highlighting traditional and modern approaches, emerging trends, and real-world applications.

II. Understanding Equipment Procurement Models

Equipment procurement models refer to the strategies and processes organizations use to acquire the necessary equipment for their operations. Selecting the right procurement model is crucial for capacitor manufacturers, as it directly impacts production efficiency, cost management, and overall competitiveness. Several factors influence procurement decisions, including market demand, technological advancements, financial constraints, and sustainability considerations.

III. Traditional Procurement Models

A. Direct Purchase Model

The direct purchase model is one of the most straightforward procurement strategies. In this model, manufacturers buy equipment outright from suppliers. The process typically involves identifying the required equipment, negotiating prices, and completing the purchase.

**Advantages:**

- Full ownership of the equipment, allowing for complete control over its use and maintenance.

- Potential for long-term cost savings, as there are no ongoing lease payments.

**Disadvantages:**

- High upfront costs can strain financial resources, especially for small manufacturers.

- Risk of obsolescence, as technology evolves rapidly in the capacitor industry.

B. Leasing Model

The leasing model allows manufacturers to use equipment without purchasing it outright. Instead, they pay a periodic fee to the equipment owner for the right to use it.

**Advantages:**

- Lower initial costs, making it easier for manufacturers to access advanced technology.

- Flexibility to upgrade equipment as technology evolves without significant financial burden.

**Disadvantages:**

- Ongoing lease payments can accumulate, potentially leading to higher long-term costs.

- Limited control over the equipment, as it remains the property of the leasing company.

C. Build-Operate-Transfer (BOT) Model

The BOT model involves a partnership between a manufacturer and a contractor. The contractor builds the facility, operates it for a specified period, and then transfers ownership to the manufacturer.

**Advantages:**

- Access to specialized expertise in building and operating equipment.

- Reduced risk for manufacturers, as they do not need to invest heavily in initial setup.

**Disadvantages:**

- Complexity in contract negotiations and management.

- Potential for misalignment of interests between the manufacturer and contractor.

IV. Modern Procurement Models

A. Just-In-Time (JIT) Procurement

Just-In-Time (JIT) procurement is a modern approach that focuses on minimizing inventory costs by acquiring equipment and materials only as needed for production.

**Benefits for Capacitor Manufacturers:**

- Reduced storage costs and waste, leading to improved profitability.

- Enhanced responsiveness to market changes, allowing manufacturers to adapt quickly to demand fluctuations.

B. Collaborative Procurement

Collaborative procurement involves multiple manufacturers working together to procure equipment and materials. This model fosters partnerships and shared resources.

**Benefits of Collaboration:**

- Cost savings through bulk purchasing and shared logistics.

- Enhanced innovation through knowledge sharing and joint problem-solving.

C. E-Procurement

E-procurement leverages technology to streamline the procurement process. This model includes online platforms for sourcing, purchasing, and managing equipment.

**Role of Technology:**

- Increased efficiency through automated processes and reduced paperwork.

- Enhanced data analytics capabilities, allowing manufacturers to make informed procurement decisions.

V. Emerging Trends in Equipment Procurement

A. Sustainability and Green Procurement

Sustainability is becoming increasingly important in the capacitor industry. Manufacturers are adopting eco-friendly practices in their procurement processes to minimize environmental impact.

**Models Supporting Eco-Friendly Practices:**

- Sourcing materials from sustainable suppliers.

- Implementing energy-efficient equipment and processes.

B. Digital Transformation in Procurement

The advent of Industry 4.0 is transforming procurement models. Digital technologies, such as artificial intelligence (AI) and data analytics, are reshaping how manufacturers approach procurement.

**Impact of Industry 4.0:**

- Enhanced decision-making through real-time data analysis.

- Improved supply chain visibility, allowing for better risk management.

C. Global Sourcing Strategies

Global sourcing involves procuring equipment and materials from international suppliers. This strategy offers several benefits but also presents challenges.

**Benefits of Global Sourcing:**

- Access to a wider range of suppliers and competitive pricing.

- Opportunities for innovation through exposure to diverse technologies.

**Challenges and Considerations:**

- Navigating international regulations and trade policies.

- Managing logistics and supply chain complexities.

VI. Case Studies

A. Successful Implementation of Modern Procurement Models

Several capacitor manufacturers have successfully implemented modern procurement models to enhance their operations. For instance, a leading capacitor manufacturer adopted a JIT procurement strategy, significantly reducing inventory costs and improving production efficiency. By closely monitoring market demand and supplier capabilities, they were able to streamline their operations and respond quickly to customer needs.

B. Lessons Learned from Industry Leaders

Industry leaders emphasize the importance of flexibility and adaptability in procurement strategies. By continuously evaluating and adjusting their procurement models, manufacturers can stay ahead of technological advancements and market trends. Collaboration and sustainability are also key themes, as manufacturers recognize the value of partnerships and eco-friendly practices in enhancing their competitive edge.

VII. Conclusion

In conclusion, the equipment procurement models of the latest capacitor group are evolving to meet the demands of a rapidly changing industry. Traditional models, such as direct purchase and leasing, still play a role, but modern approaches like JIT procurement, collaborative procurement, and e-procurement are gaining traction. Emerging trends, including sustainability and digital transformation, are reshaping procurement strategies, enabling manufacturers to enhance efficiency and competitiveness.

As the capacitor industry continues to innovate, manufacturers must remain agile and open to adopting new procurement models. By doing so, they can navigate the complexities of the market and position themselves for future success.

VIII. References

1. Smith, J. (2022). *Trends in Capacitor Technology: A Comprehensive Overview*. Journal of Electronic Components.

2. Johnson, L. (2023). *Sustainable Practices in the Capacitor Industry*. Green Manufacturing Review.

3. Lee, R. (2023). *Digital Transformation in Procurement: Opportunities and Challenges*. International Journal of Supply Chain Management.

4. Patel, A. (2023). *Collaborative Procurement: A New Era for Manufacturers*. Manufacturing Insights.

This blog post provides a comprehensive exploration of the equipment procurement models in the capacitor industry, offering insights into traditional and modern approaches, emerging trends, and real-world applications.