Integrated circuit device product training considerations

Integrated Circuit Device Product Training Considerations

I. Introduction

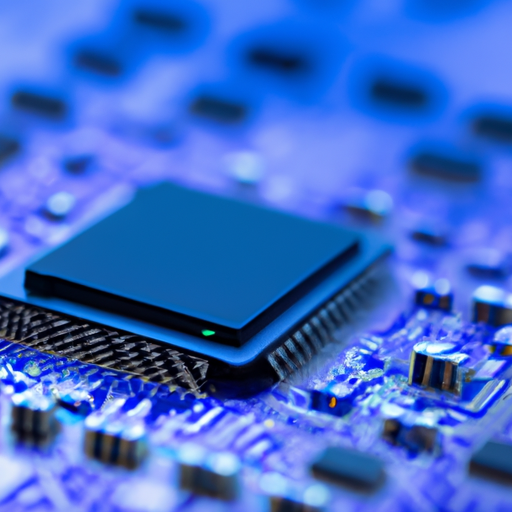

Integrated circuits (ICs) are the backbone of modern electronic devices, enabling functionality in everything from smartphones to automotive systems. These miniaturized circuits, which combine multiple electronic components into a single chip, have revolutionized technology and continue to drive innovation across various industries. As the demand for advanced ICs grows, so does the need for effective training programs that equip professionals with the necessary skills and knowledge. This blog post explores the key considerations for training in integrated circuit device products, emphasizing the importance of a well-structured training program.

II. Understanding Integrated Circuits

A. Overview of IC Technology

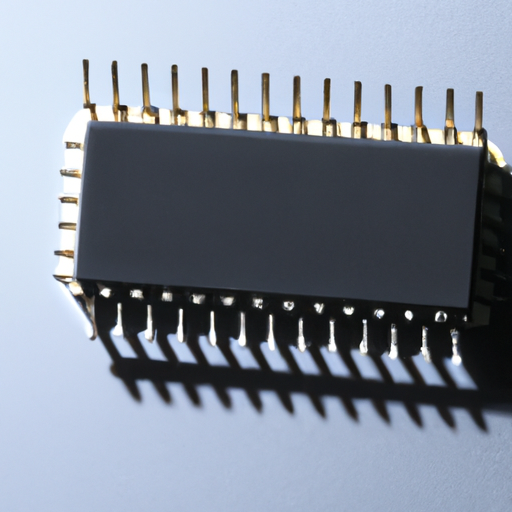

Integrated circuits can be categorized into three main types: analog, digital, and mixed-signal. Analog ICs process continuous signals, digital ICs handle discrete signals, and mixed-signal ICs combine both types. Each category serves distinct functions and applications, making it essential for trainees to understand the differences and specific use cases.

Key components of ICs include transistors, resistors, and capacitors. Transistors act as switches or amplifiers, resistors control current flow, and capacitors store electrical energy. A solid grasp of these components is crucial for anyone involved in IC design, manufacturing, or testing.

B. Applications of ICs

ICs are ubiquitous in modern technology, with applications spanning various sectors:

1. **Consumer Electronics**: From smartphones to televisions, ICs are integral to the functionality of everyday devices.

2. **Automotive Systems**: Modern vehicles rely on ICs for engine control, safety features, and infotainment systems.

3. **Industrial Automation**: ICs facilitate automation processes, improving efficiency and productivity in manufacturing.

4. **Telecommunications**: ICs enable communication technologies, including mobile networks and satellite systems.

Understanding these applications helps trainees appreciate the significance of their work and the impact of IC technology on society.

III. Training Objectives

A. Knowledge Acquisition

The primary objective of IC training is to ensure participants acquire a robust technical understanding of IC design and functionality. This includes familiarizing them with the principles of circuit design, the intricacies of manufacturing processes, and the latest advancements in IC technology.

B. Skill Development

Hands-on experience is vital in IC training. Trainees should engage in practical exercises that enhance their skills in IC testing and troubleshooting. Proficiency in using design software and tools is also essential, as these are integral to the design and validation of ICs.

C. Awareness of Industry Standards and Regulations

IC professionals must be aware of industry standards and regulations that govern their work. Training should cover relevant guidelines, such as ISO and IPC standards, ensuring that participants understand the importance of compliance in their roles.

IV. Target Audience

The target audience for IC training programs is diverse, encompassing:

1. **Engineers and Technicians**: Those directly involved in IC design, testing, and manufacturing.

2. **Product Managers and Marketing Teams**: Professionals who need to understand the technical aspects of ICs to effectively market products.

3. **Quality Assurance and Compliance Personnel**: Individuals responsible for ensuring that products meet industry standards and regulations.

4. **New Hires and Interns**: Entry-level employees who require foundational knowledge and skills in IC technology.

Tailoring training content to meet the needs of these varied groups is essential for maximizing the effectiveness of the program.

V. Training Content

A. Technical Modules

Training should include comprehensive technical modules covering:

1. **IC Design Principles**: Fundamental concepts of circuit design, including schematic capture and layout design.

2. **Fabrication Processes**: An overview of the manufacturing processes involved in IC production, including photolithography and etching.

3. **Testing and Validation Methods**: Techniques for ensuring IC functionality and reliability, including functional testing and stress testing.

B. Practical Workshops

Hands-on workshops are crucial for reinforcing theoretical knowledge. These may include:

1. **Circuit Simulation and Modeling**: Using software tools to simulate circuit behavior before physical implementation.

2. **Soldering and Assembly Techniques**: Practical exercises in assembling ICs and soldering components.

3. **Debugging and Troubleshooting Exercises**: Real-world scenarios where trainees diagnose and resolve issues in ICs.

C. Industry Standards

Training should also address industry standards, including:

1. **ISO and IPC Standards**: Guidelines that ensure quality and safety in IC manufacturing and testing.

2. **Safety and Environmental Regulations**: Compliance with regulations that protect workers and the environment during IC production.

VI. Training Methods

A. Classroom Instruction

Traditional classroom instruction remains a valuable training method. This can include:

1. **Lectures and Presentations**: Expert-led sessions that provide foundational knowledge.

2. **Interactive Discussions**: Opportunities for participants to engage with instructors and peers, fostering a collaborative learning environment.

B. Online Learning

With the rise of digital education, online learning platforms offer flexibility and accessibility. This can include:

1. **E-learning Platforms and Resources**: Self-paced courses that allow participants to learn at their convenience.

2. **Webinars and Virtual Workshops**: Live sessions that facilitate real-time interaction and knowledge sharing.

C. Hands-on Training

Practical experience is essential for effective learning. This can involve:

1. **Lab Sessions and Practical Exercises**: Opportunities for trainees to apply their knowledge in a controlled environment.

2. **Field Visits to Manufacturing Facilities**: Exposure to real-world manufacturing processes and practices.

VII. Assessment and Evaluation

A. Pre-training Assessments

Before training begins, conducting assessments can help identify knowledge gaps among participants. This allows for the tailoring of training content to meet specific needs.

B. Ongoing Evaluations

Throughout the training program, ongoing evaluations can include:

1. **Quizzes and Tests**: Regular assessments to gauge understanding and retention of material.

2. **Practical Assessments**: Evaluating hands-on skills through practical exercises.

C. Post-training Feedback

After training, gathering feedback is crucial for continuous improvement. This can involve:

1. **Surveys and Interviews**: Collecting participant insights on the training experience.

2. **Continuous Improvement of Training Programs**: Using feedback to refine and enhance future training initiatives.

VIII. Challenges in Training

Training in integrated circuits is not without its challenges. Some of the key obstacles include:

A. Rapid Technological Advancements

The pace of technological change in the IC industry can make it difficult to keep training content current. Training programs must be regularly updated to reflect the latest developments.

B. Diverse Learning Styles and Backgrounds

Participants may come from various educational and professional backgrounds, necessitating a flexible approach to training that accommodates different learning styles.

C. Resource Constraints

Limited resources, including time, budget, and materials, can hinder the effectiveness of training programs. Organizations must prioritize training and allocate sufficient resources to ensure success.

IX. Best Practices for Effective Training

To maximize the effectiveness of IC training programs, organizations should consider the following best practices:

A. Customizing Training Programs

Tailoring training content to meet the specific needs of the target audience ensures relevance and engagement.

B. Incorporating Real-world Examples

Using case studies and real-world examples helps participants connect theoretical knowledge to practical applications.

C. Encouraging Collaboration

Fostering a collaborative learning environment encourages knowledge sharing and peer support among participants.

D. Providing Ongoing Support

Offering resources and support beyond the training program helps participants continue their learning journey and apply their skills effectively.

X. Conclusion

In conclusion, training in integrated circuit device products is essential for equipping professionals with the knowledge and skills needed to thrive in a rapidly evolving industry. By understanding the importance of ICs, setting clear training objectives, and implementing effective training methods, organizations can ensure their workforce is prepared for the challenges ahead. As technology continues to advance, investing in comprehensive training programs will be crucial for staying competitive and driving innovation in the field of integrated circuits.

XI. References

1. Academic journals and articles on integrated circuit technology.

2. Industry reports and white papers from leading semiconductor organizations.

3. Relevant textbooks and online resources for further reading on IC design and manufacturing.

By focusing on these training considerations, organizations can build a skilled workforce capable of navigating the complexities of integrated circuit technology and contributing to the future of innovation.

Integrated Circuit Device Product Training Considerations

I. Introduction

Integrated circuits (ICs) are the backbone of modern electronic devices, enabling functionality in everything from smartphones to automotive systems. These miniaturized circuits, which combine multiple electronic components into a single chip, have revolutionized technology and continue to drive innovation across various industries. As the demand for advanced ICs grows, so does the need for effective training programs that equip professionals with the necessary skills and knowledge. This blog post explores the key considerations for training in integrated circuit device products, emphasizing the importance of a well-structured training program.

II. Understanding Integrated Circuits

A. Overview of IC Technology

Integrated circuits can be categorized into three main types: analog, digital, and mixed-signal. Analog ICs process continuous signals, digital ICs handle discrete signals, and mixed-signal ICs combine both types. Each category serves distinct functions and applications, making it essential for trainees to understand the differences and specific use cases.

Key components of ICs include transistors, resistors, and capacitors. Transistors act as switches or amplifiers, resistors control current flow, and capacitors store electrical energy. A solid grasp of these components is crucial for anyone involved in IC design, manufacturing, or testing.

B. Applications of ICs

ICs are ubiquitous in modern technology, with applications spanning various sectors:

1. **Consumer Electronics**: From smartphones to televisions, ICs are integral to the functionality of everyday devices.

2. **Automotive Systems**: Modern vehicles rely on ICs for engine control, safety features, and infotainment systems.

3. **Industrial Automation**: ICs facilitate automation processes, improving efficiency and productivity in manufacturing.

4. **Telecommunications**: ICs enable communication technologies, including mobile networks and satellite systems.

Understanding these applications helps trainees appreciate the significance of their work and the impact of IC technology on society.

III. Training Objectives

A. Knowledge Acquisition

The primary objective of IC training is to ensure participants acquire a robust technical understanding of IC design and functionality. This includes familiarizing them with the principles of circuit design, the intricacies of manufacturing processes, and the latest advancements in IC technology.

B. Skill Development

Hands-on experience is vital in IC training. Trainees should engage in practical exercises that enhance their skills in IC testing and troubleshooting. Proficiency in using design software and tools is also essential, as these are integral to the design and validation of ICs.

C. Awareness of Industry Standards and Regulations

IC professionals must be aware of industry standards and regulations that govern their work. Training should cover relevant guidelines, such as ISO and IPC standards, ensuring that participants understand the importance of compliance in their roles.

IV. Target Audience

The target audience for IC training programs is diverse, encompassing:

1. **Engineers and Technicians**: Those directly involved in IC design, testing, and manufacturing.

2. **Product Managers and Marketing Teams**: Professionals who need to understand the technical aspects of ICs to effectively market products.

3. **Quality Assurance and Compliance Personnel**: Individuals responsible for ensuring that products meet industry standards and regulations.

4. **New Hires and Interns**: Entry-level employees who require foundational knowledge and skills in IC technology.

Tailoring training content to meet the needs of these varied groups is essential for maximizing the effectiveness of the program.

V. Training Content

A. Technical Modules

Training should include comprehensive technical modules covering:

1. **IC Design Principles**: Fundamental concepts of circuit design, including schematic capture and layout design.

2. **Fabrication Processes**: An overview of the manufacturing processes involved in IC production, including photolithography and etching.

3. **Testing and Validation Methods**: Techniques for ensuring IC functionality and reliability, including functional testing and stress testing.

B. Practical Workshops

Hands-on workshops are crucial for reinforcing theoretical knowledge. These may include:

1. **Circuit Simulation and Modeling**: Using software tools to simulate circuit behavior before physical implementation.

2. **Soldering and Assembly Techniques**: Practical exercises in assembling ICs and soldering components.

3. **Debugging and Troubleshooting Exercises**: Real-world scenarios where trainees diagnose and resolve issues in ICs.

C. Industry Standards

Training should also address industry standards, including:

1. **ISO and IPC Standards**: Guidelines that ensure quality and safety in IC manufacturing and testing.

2. **Safety and Environmental Regulations**: Compliance with regulations that protect workers and the environment during IC production.

VI. Training Methods

A. Classroom Instruction

Traditional classroom instruction remains a valuable training method. This can include:

1. **Lectures and Presentations**: Expert-led sessions that provide foundational knowledge.

2. **Interactive Discussions**: Opportunities for participants to engage with instructors and peers, fostering a collaborative learning environment.

B. Online Learning

With the rise of digital education, online learning platforms offer flexibility and accessibility. This can include:

1. **E-learning Platforms and Resources**: Self-paced courses that allow participants to learn at their convenience.

2. **Webinars and Virtual Workshops**: Live sessions that facilitate real-time interaction and knowledge sharing.

C. Hands-on Training

Practical experience is essential for effective learning. This can involve:

1. **Lab Sessions and Practical Exercises**: Opportunities for trainees to apply their knowledge in a controlled environment.

2. **Field Visits to Manufacturing Facilities**: Exposure to real-world manufacturing processes and practices.

VII. Assessment and Evaluation

A. Pre-training Assessments

Before training begins, conducting assessments can help identify knowledge gaps among participants. This allows for the tailoring of training content to meet specific needs.

B. Ongoing Evaluations

Throughout the training program, ongoing evaluations can include:

1. **Quizzes and Tests**: Regular assessments to gauge understanding and retention of material.

2. **Practical Assessments**: Evaluating hands-on skills through practical exercises.

C. Post-training Feedback

After training, gathering feedback is crucial for continuous improvement. This can involve:

1. **Surveys and Interviews**: Collecting participant insights on the training experience.

2. **Continuous Improvement of Training Programs**: Using feedback to refine and enhance future training initiatives.

VIII. Challenges in Training

Training in integrated circuits is not without its challenges. Some of the key obstacles include:

A. Rapid Technological Advancements

The pace of technological change in the IC industry can make it difficult to keep training content current. Training programs must be regularly updated to reflect the latest developments.

B. Diverse Learning Styles and Backgrounds

Participants may come from various educational and professional backgrounds, necessitating a flexible approach to training that accommodates different learning styles.

C. Resource Constraints

Limited resources, including time, budget, and materials, can hinder the effectiveness of training programs. Organizations must prioritize training and allocate sufficient resources to ensure success.

IX. Best Practices for Effective Training

To maximize the effectiveness of IC training programs, organizations should consider the following best practices:

A. Customizing Training Programs

Tailoring training content to meet the specific needs of the target audience ensures relevance and engagement.

B. Incorporating Real-world Examples

Using case studies and real-world examples helps participants connect theoretical knowledge to practical applications.

C. Encouraging Collaboration

Fostering a collaborative learning environment encourages knowledge sharing and peer support among participants.

D. Providing Ongoing Support

Offering resources and support beyond the training program helps participants continue their learning journey and apply their skills effectively.

X. Conclusion

In conclusion, training in integrated circuit device products is essential for equipping professionals with the knowledge and skills needed to thrive in a rapidly evolving industry. By understanding the importance of ICs, setting clear training objectives, and implementing effective training methods, organizations can ensure their workforce is prepared for the challenges ahead. As technology continues to advance, investing in comprehensive training programs will be crucial for staying competitive and driving innovation in the field of integrated circuits.

XI. References

1. Academic journals and articles on integrated circuit technology.

2. Industry reports and white papers from leading semiconductor organizations.

3. Relevant textbooks and online resources for further reading on IC design and manufacturing.

By focusing on these training considerations, organizations can build a skilled workforce capable of navigating the complexities of integrated circuit technology and contributing to the future of innovation.