What are the development trends in the resistor industry?

Development Trends in the Resistor Industry

I. Introduction

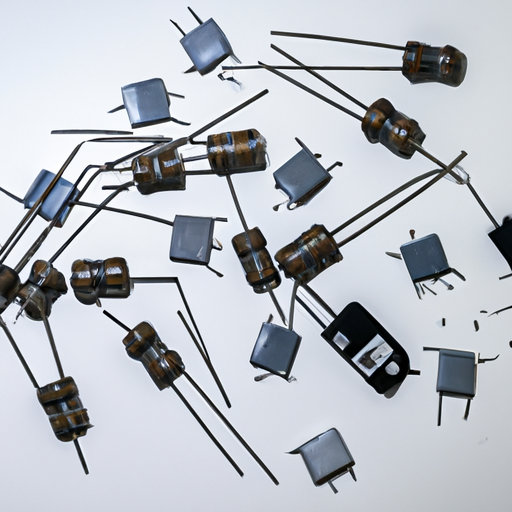

Resistors are fundamental components in electronic circuits, serving the critical function of controlling current flow and voltage levels. They are essential in a wide range of applications, from simple household devices to complex industrial machinery. The resistor industry plays a vital role in the broader electronics market, influencing the performance and reliability of countless electronic products. This article aims to explore the current and emerging trends in the resistor industry, shedding light on how these trends are shaping the future of electronics.

II. Historical Context

A. Brief Overview of the Evolution of Resistors

The history of resistors dates back to the early days of electricity. The first resistors were made from simple materials like carbon and wire, which were used to limit current in circuits. As technology advanced, so did the materials and designs of resistors. The introduction of metal film and wire-wound resistors marked significant milestones, allowing for greater precision and reliability.

B. The Growth of the Electronics Industry and Its Impact on Resistor Development

The rapid growth of the electronics industry, particularly in the latter half of the 20th century, has had a profound impact on resistor development. As consumer electronics became more prevalent, the demand for smaller, more efficient components surged. This demand has driven innovation in resistor technology, leading to the development of new materials and manufacturing techniques that cater to the evolving needs of the market.

III. Current Trends in the Resistor Industry

A. Miniaturization of Resistors

One of the most significant trends in the resistor industry is the miniaturization of components. As consumer electronics become increasingly compact, there is a growing demand for smaller resistors that can fit into tight spaces without compromising performance. Advances in manufacturing techniques, such as surface mount technology (SMT), have enabled the production of miniature resistors that maintain high levels of accuracy and reliability.

B. Increased Power Ratings

With the rise of industrial applications requiring high-power resistors, manufacturers are focusing on developing components that can withstand greater power ratings. This trend is driven by the need for resistors in applications such as electric vehicles, renewable energy systems, and industrial automation. New materials, such as ceramic and metal alloys, are being explored to enhance the thermal stability and power handling capabilities of resistors.

C. Enhanced Precision and Tolerance

In modern electronic applications, precision and tolerance are paramount. The demand for high-precision resistors has led to innovations in design and manufacturing processes. Techniques such as laser trimming and advanced coating methods are being employed to produce resistors with tighter tolerances, ensuring that they meet the stringent requirements of applications in telecommunications, aerospace, and medical devices.

D. Environmental Considerations

As environmental concerns continue to grow, the resistor industry is shifting towards eco-friendly materials and processes. Manufacturers are increasingly focusing on compliance with global environmental regulations, such as the Restriction of Hazardous Substances (RoHS) directive. This shift is prompting the development of resistors made from sustainable materials and the adoption of greener manufacturing practices, reducing the industry's overall environmental footprint.

IV. Emerging Technologies and Innovations

A. Smart Resistors

The advent of the Internet of Things (IoT) has paved the way for the development of smart resistors. These advanced components can monitor and adjust their resistance in real-time, providing enhanced functionality in smart devices. Applications range from energy management systems to wearable technology, where smart resistors can optimize performance and improve energy efficiency.

B. Thin-Film and Thick-Film Technologies

Thin-film and thick-film technologies represent two distinct approaches to resistor manufacturing. Thin-film resistors are known for their high precision and stability, making them ideal for applications requiring tight tolerances. In contrast, thick-film resistors offer greater power handling capabilities and are often used in high-power applications. Understanding the advantages and applications of each technology is crucial for manufacturers and designers looking to select the right resistor for their needs.

C. Use of Nanotechnology

Nanotechnology is revolutionizing resistor design by enabling the creation of components with enhanced performance and efficiency. By manipulating materials at the nanoscale, manufacturers can develop resistors with improved thermal conductivity, reduced noise, and greater stability. This innovation holds the potential to significantly enhance the performance of electronic devices, particularly in high-frequency applications.

V. Market Dynamics

A. Global Market Overview

The global resistor market is characterized by a diverse range of players, from established manufacturers to emerging startups. Key players include Vishay Intertechnology, Yageo Corporation, and Panasonic, among others. The market is projected to experience steady growth, driven by the increasing demand for electronic devices across various sectors, including automotive, telecommunications, and consumer electronics.

B. Regional Trends

Regional trends play a significant role in shaping the resistor market. North America and Europe have traditionally been strong markets for resistors, driven by advanced technology sectors and stringent quality standards. However, the Asia-Pacific region is witnessing rapid growth, fueled by the expansion of manufacturing capabilities and the rising demand for consumer electronics. Factors such as government initiatives to promote electronics manufacturing and the growth of the automotive industry are contributing to this trend.

C. Impact of Supply Chain Issues

The COVID-19 pandemic has highlighted vulnerabilities in global supply chains, affecting the resistor industry significantly. Disruptions in manufacturing and logistics have led to shortages of raw materials and components, impacting production timelines and costs. As the industry recovers, companies are reevaluating their supply chain strategies to enhance resilience and mitigate future risks.

VI. Future Outlook

A. Predictions for the Resistor Industry

Looking ahead, the resistor industry is expected to witness several technological advancements. Innovations in materials science, such as the development of new alloys and composites, will likely enhance the performance of resistors. Additionally, the growing trend towards automation and smart technologies will drive demand for advanced resistor solutions that can integrate seamlessly into modern electronic systems.

B. Challenges Ahead

Despite the positive outlook, the resistor industry faces challenges, including competition from alternative technologies such as digital resistors and the ongoing push for sustainability. Manufacturers will need to adapt to changing consumer preferences and regulatory requirements to remain competitive in the evolving market landscape.

VII. Conclusion

In summary, the resistor industry is undergoing significant transformations driven by technological advancements, market demands, and environmental considerations. The trends of miniaturization, increased power ratings, enhanced precision, and the adoption of eco-friendly practices are shaping the future of resistors. As the electronics landscape continues to evolve, the importance of adaptability and innovation in the resistor industry cannot be overstated. Resistors will remain a crucial component in the development of advanced electronic systems, ensuring their reliability and performance in an increasingly complex world.

VIII. References

1. Vishay Intertechnology. (2023). Resistor Technology Overview.

2. Yageo Corporation. (2023). Market Trends in Resistor Manufacturing.

3. Panasonic. (2023). Innovations in Resistor Technology.

4. IEEE Xplore. (2023). Advances in Resistor Design and Applications.

5. Journal of Electronic Materials. (2023). The Role of Nanotechnology in Resistor Development.

This blog post provides a comprehensive overview of the development trends in the resistor industry, highlighting the historical context, current trends, emerging technologies, market dynamics, and future outlook. Each section is designed to inform readers about the critical aspects of the resistor industry and its significance in the broader electronics market.