What are the comparative differences between mainstream low-voltage capacitor models?

Comparative Differences Between Mainstream Low-Voltage Capacitor Models

I. Introduction

Capacitors are essential components in electrical and electronic circuits, serving various functions such as energy storage, filtering, and signal coupling. Low-voltage capacitors, specifically, are designed to operate at voltages typically below 100 volts, making them suitable for a wide range of applications, from consumer electronics to industrial machinery. This article aims to compare mainstream low-voltage capacitor models, highlighting their differences in construction, performance metrics, and suitability for specific applications.

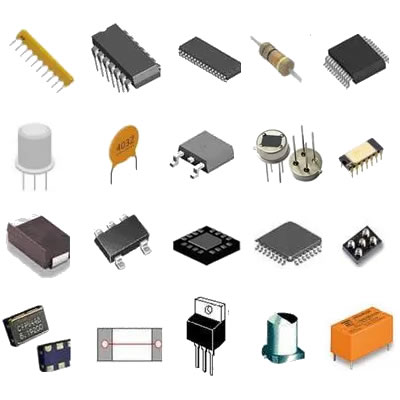

II. Overview of Low-Voltage Capacitor Types

A. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that use an electrolyte as one of their plates. They are known for their high capacitance values, making them ideal for applications requiring significant energy storage. Commonly used in power supply circuits, audio equipment, and smoothing applications, electrolytic capacitors are typically constructed from aluminum or tantalum.

**Characteristics and Applications:**

Electrolytic capacitors offer high capacitance values (up to several thousand microfarads) and relatively low cost. However, they have a limited voltage rating and can be sensitive to temperature and ripple current, which can affect their lifespan.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized capacitors made from ceramic materials. They are widely used in high-frequency applications due to their low equivalent series resistance (ESR) and excellent stability over temperature and voltage.

**Characteristics and Applications:**

Ceramic capacitors are available in a wide range of capacitance values, typically from a few picofarads to several microfarads. They are commonly used in decoupling, filtering, and timing applications. Their small size and reliability make them a popular choice in consumer electronics.

C. Film Capacitors

Film capacitors are constructed using thin plastic films as the dielectric material. They are known for their stability, low ESR, and high insulation resistance, making them suitable for applications requiring precision and reliability.

**Characteristics and Applications:**

Film capacitors are available in various types, including polyester, polypropylene, and polycarbonate. They are often used in audio equipment, power electronics, and applications requiring high voltage and current handling. Their long lifespan and low self-heating characteristics make them a preferred choice in many applications.

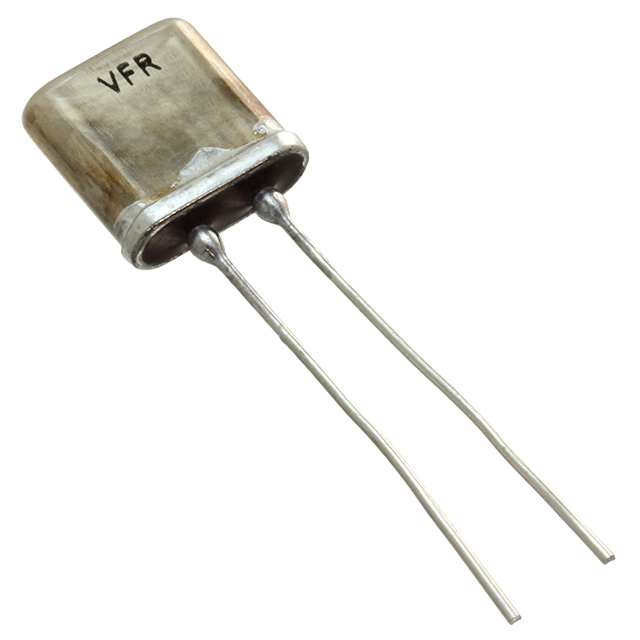

D. Tantalum Capacitors

Tantalum capacitors are another type of electrolytic capacitor, but they use tantalum metal for the anode. They are known for their high capacitance values and stable performance over a wide range of temperatures and voltages.

**Characteristics and Applications:**

Tantalum capacitors are often used in applications where space is limited, such as in mobile devices and compact electronic circuits. They offer excellent reliability and performance but can be more expensive than other types of capacitors.

III. Key Performance Metrics

A. Capacitance Value

The capacitance value of a capacitor is a critical factor that determines its suitability for specific applications. Electrolytic capacitors typically offer the highest capacitance values, while ceramic capacitors are available in a broader range of lower values. Film and tantalum capacitors fall in between, with tantalum capacitors often providing higher capacitance in smaller packages.

B. Voltage Rating

The voltage rating of a capacitor indicates the maximum voltage it can handle without failure. Electrolytic capacitors generally have lower voltage ratings compared to ceramic and film capacitors. This is crucial in applications where voltage spikes can occur, as exceeding the voltage rating can lead to catastrophic failure.

C. Equivalent Series Resistance (ESR)

ESR is a measure of the resistance a capacitor presents to alternating current (AC). Lower ESR values are desirable, especially in high-frequency applications, as they lead to better performance and efficiency. Ceramic capacitors typically have the lowest ESR, followed by film and tantalum capacitors, with electrolytic capacitors having the highest ESR.

D. Temperature Coefficient

The temperature coefficient indicates how a capacitor's capacitance changes with temperature. Ceramic capacitors can have varying temperature coefficients depending on their dielectric material, while film capacitors generally exhibit stable performance across temperature ranges. Electrolytic and tantalum capacitors can be more sensitive to temperature variations.

E. Lifetime and Reliability

The lifespan of a capacitor is influenced by factors such as operating temperature, voltage, and ripple current. Film capacitors are known for their long lifespan and reliability, while electrolytic capacitors may have shorter lifespans due to their sensitivity to environmental conditions. Tantalum capacitors offer good reliability but can fail catastrophically if subjected to overvoltage.

IV. Comparative Analysis of Mainstream Models

A. Popular Electrolytic Capacitor Models

Common models include the Panasonic EEU-FR series and the Nichicon UHE series. These capacitors are known for their high capacitance values and affordability, making them suitable for power supply applications. However, they may have limitations in terms of voltage ratings and temperature stability.

B. Leading Ceramic Capacitor Models

The Murata GRM series and the TDK C3216 series are popular choices in the ceramic capacitor market. They offer low ESR and high stability, making them ideal for decoupling and filtering applications in high-frequency circuits. Their compact size and reliability are significant advantages.

C. Notable Film Capacitor Models

The WIMA MKS series and the Vishay BC Components 1832 series are well-regarded film capacitors. They provide excellent performance in audio and power applications, with low ESR and high voltage ratings. Their long lifespan and stability make them a preferred choice for critical applications.

D. Common Tantalum Capacitor Models

The Kemet T491 series and the AVX TPS series are notable tantalum capacitors. They offer high capacitance in small packages, making them suitable for space-constrained applications. However, their higher cost and sensitivity to overvoltage are considerations for designers.

V. Application-Specific Considerations

A. Consumer Electronics

In consumer electronics, capacitors are often used for decoupling and filtering. Ceramic capacitors are preferred for their low ESR and compact size, while electrolytic capacitors are used for power supply applications due to their high capacitance.

B. Industrial Applications

Industrial applications may require capacitors that can handle higher voltages and currents. Film capacitors are often favored for their reliability and performance in power electronics, while tantalum capacitors are used in compact devices.

C. Automotive Applications

Automotive applications demand capacitors that can withstand harsh environments. Tantalum capacitors are commonly used in automotive electronics due to their reliability, while film capacitors are used in power management systems.

D. Renewable Energy Systems

In renewable energy systems, capacitors play a crucial role in energy storage and power conditioning. Film and electrolytic capacitors are often used in inverters and energy storage systems due to their high capacitance and reliability.

VI. Future Trends in Low-Voltage Capacitor Technology

The future of low-voltage capacitors is likely to be shaped by innovations in materials and design. Emerging technologies, such as flexible electronics and energy harvesting, will drive the development of new capacitor types. Additionally, sustainability and environmental considerations are becoming increasingly important, leading to the exploration of eco-friendly materials and manufacturing processes.

VII. Conclusion

In summary, the comparative differences between mainstream low-voltage capacitor models highlight the importance of selecting the right capacitor for specific applications. Each type of capacitor—electrolytic, ceramic, film, and tantalum—has its unique characteristics, advantages, and disadvantages. Understanding these differences is crucial for engineers and designers to ensure optimal performance and reliability in their electronic circuits. As technology continues to evolve, the future of low-voltage capacitors promises exciting advancements that will further enhance their capabilities and applications.

VIII. References

1. "Capacitor Basics: Types and Applications." Electronics Tutorials.

2. "Understanding Capacitor Specifications." Digi-Key Electronics.

3. "The Role of Capacitors in Power Electronics." IEEE Transactions on Power Electronics.

4. "Future Trends in Capacitor Technology." Journal of Electronic Materials.