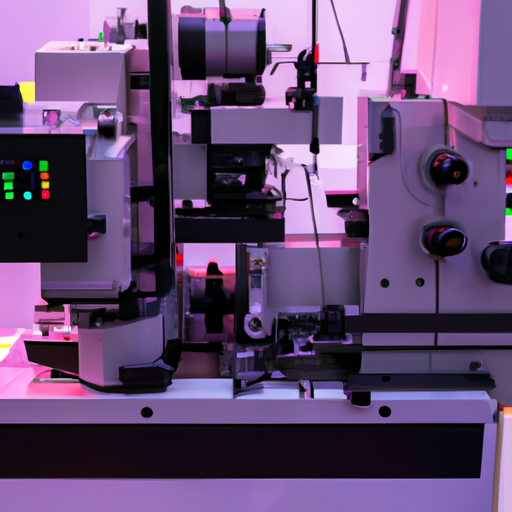

CFR-50JB-52-1K3 Optical Inspection Equipment highlighting the core functional technology articles and application development cases of Optical Inspection Equipment that are effective.

CFR-50JB-52-1K3 Optical Inspection Equipment: Core Functional Technologies and Application Development Cases

The CFR-50JB-52-1K3 Optical Inspection Equipment represents a significant advancement in the field of quality control and inspection across various industries. Below, we delve into the core functional technologies that underpin this sophisticated tool, along with notable application development cases that demonstrate its effectiveness.

Core Functional Technologies

| 1. High-Resolution Imaging | |

| 2. Automated Defect Detection | |

| 3. 3D Imaging and Measurement | |

| 4. Multi-Spectral Imaging | |

| 5. Image Processing Algorithms | |

| 6. Integration with Automation Systems | |

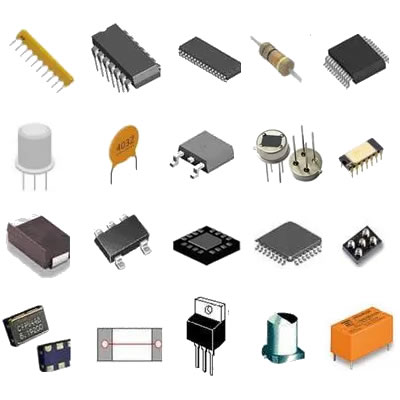

| 1. Semiconductor Manufacturing | |

| 2. Automotive Industry | |

| 3. Pharmaceuticals | |

| 4. Consumer Electronics | |

| 5. Food Industry | |

| 6. Textile Industry |

Application Development Cases

Conclusion

The CFR-50JB-52-1K3 Optical Inspection Equipment exemplifies the forefront of optical inspection technology, showcasing its versatility and effectiveness across diverse industries. With features such as high-resolution imaging, automated defect detection, and advanced image processing algorithms, this equipment significantly enhances quality control processes. The application development cases illustrate the tangible benefits of adopting optical inspection systems, including improved product quality, increased efficiency, and compliance with industry standards. As technology continues to advance, the role of optical inspection equipment is poised to expand, driving further innovation in manufacturing and quality assurance.