What are the important product categories of capacitor cabinets?

Important Product Categories of Capacitor Cabinets

I. Introduction

Capacitor cabinets are essential components in electrical systems, playing a crucial role in enhancing the efficiency and reliability of power distribution. These cabinets house capacitors and associated equipment that help manage reactive power, improve power factor, and stabilize voltage levels in electrical networks. As industries and commercial establishments increasingly rely on efficient energy management, understanding the various product categories of capacitor cabinets becomes vital. This article will explore the different types of capacitor cabinets, their functionalities, applications, and the factors to consider when selecting the right one for specific needs.

II. Understanding Capacitor Cabinets

A. Functionality of Capacitor Cabinets

Capacitor cabinets serve two primary functions in electrical systems:

1. **Power Factor Correction**: Capacitors are used to counteract the inductive effects of motors and transformers, which can lead to a lagging power factor. By improving the power factor, capacitor cabinets help reduce energy losses and lower electricity costs.

2. **Voltage Regulation**: Capacitor cabinets help maintain voltage levels within acceptable limits, ensuring that electrical equipment operates efficiently and reliably. This is particularly important in industrial settings where voltage fluctuations can lead to equipment damage or operational downtime.

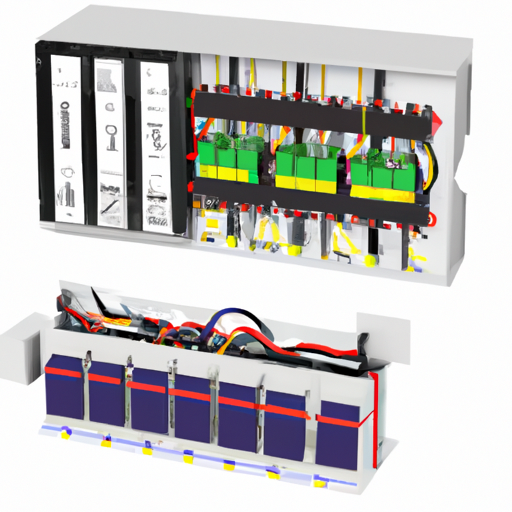

B. Components of Capacitor Cabinets

A typical capacitor cabinet consists of several key components:

1. **Capacitors**: The primary component, capacitors store electrical energy and release it as needed to improve power factor and voltage stability.

2. **Contactors**: These are electromechanical switches that control the connection and disconnection of capacitors from the electrical system.

3. **Fuses**: Fuses protect the circuit from overloads and short circuits, ensuring the safety of the capacitor cabinet.

4. **Control Panels**: These panels monitor and control the operation of the capacitor cabinet, providing essential data and allowing for automated adjustments.

5. **Enclosures**: The physical housing of the capacitor cabinet, which protects the internal components from environmental factors and ensures safety.

III. Key Product Categories of Capacitor Cabinets

A. Fixed Capacitor Cabinets

1. Description and Features

Fixed capacitor cabinets are designed to provide a constant level of reactive power compensation. They consist of a set number of capacitors that are permanently connected to the electrical system.

2. Applications

These cabinets are commonly used in industrial plants, commercial buildings, and substations where the load is relatively stable and predictable.

3. Advantages and Disadvantages

**Advantages**:

- Simple design and installation.

- Cost-effective for applications with consistent power factor needs.

**Disadvantages**:

- Limited flexibility; cannot adjust to varying load conditions.

- May lead to overcompensation during low load periods.

B. Automatic Capacitor Banks

1. Description and Features

Automatic capacitor banks are equipped with control systems that automatically adjust the number of capacitors connected to the circuit based on real-time power factor measurements.

2. Applications

These systems are ideal for facilities with fluctuating loads, such as manufacturing plants and commercial buildings with variable equipment usage.

3. Advantages and Disadvantages

**Advantages**:

- Dynamic response to changing load conditions.

- Improved energy efficiency and reduced electricity costs.

**Disadvantages**:

- Higher initial investment compared to fixed systems.

- More complex installation and maintenance requirements.

C. Harmonic Filter Capacitor Cabinets

1. Description and Features

Harmonic filter capacitor cabinets are designed to mitigate harmonic distortion in electrical systems. They combine capacitors with inductors to create a filter that reduces specific harmonic frequencies.

2. Applications

These cabinets are commonly used in facilities with non-linear loads, such as data centers, industrial drives, and renewable energy systems.

3. Advantages and Disadvantages

**Advantages**:

- Improved power quality and reduced equipment stress.

- Enhanced system reliability and efficiency.

**Disadvantages**:

- More complex design and higher costs.

- Requires careful tuning to match the specific harmonic profile of the system.

D. Power Factor Correction Panels

1. Description and Features

Power factor correction panels are integrated systems that include capacitors, control equipment, and protective devices, all housed in a single panel.

2. Applications

These panels are suitable for a wide range of applications, from small commercial buildings to large industrial facilities.

3. Advantages and Disadvantages

**Advantages**:

- Compact design and ease of installation.

- Comprehensive solution for power factor correction.

**Disadvantages**:

- Limited scalability; may require replacement for larger applications.

- Initial costs can be higher than standalone capacitor solutions.

E. Modular Capacitor Cabinets

1. Description and Features

Modular capacitor cabinets consist of multiple smaller units that can be combined to create a larger system. This design allows for flexibility in capacity and configuration.

2. Applications

These cabinets are ideal for facilities that anticipate future expansion or changes in load requirements.

3. Advantages and Disadvantages

**Advantages**:

- Scalability and adaptability to changing needs.

- Simplified maintenance and replacement of individual modules.

**Disadvantages**:

- Potentially higher costs due to modular components.

- Requires careful planning to ensure compatibility between modules.

F. Outdoor Capacitor Cabinets

1. Description and Features

Outdoor capacitor cabinets are designed to withstand environmental conditions, featuring weatherproof enclosures and robust components.

2. Applications

These cabinets are commonly used in outdoor substations, renewable energy installations, and industrial sites where space is limited.

3. Advantages and Disadvantages

**Advantages**:

- Durable and weather-resistant design.

- Suitable for a variety of outdoor applications.

**Disadvantages**:

- Higher costs due to specialized materials and construction.

- Installation may require additional site preparation.

IV. Factors to Consider When Choosing Capacitor Cabinets

When selecting a capacitor cabinet, several factors should be taken into account:

A. Application Requirements

Understanding the specific needs of the application, including load characteristics and power factor goals, is crucial for selecting the right type of capacitor cabinet.

B. Environmental Conditions

Consideration of the installation environment, such as temperature, humidity, and exposure to elements, will influence the choice of cabinet design and materials.

C. Size and Space Constraints

The physical dimensions of the capacitor cabinet must fit within the available space, and modular options may be preferable for limited areas.

D. Budget Considerations

Cost is always a factor; balancing initial investment with long-term savings from improved energy efficiency is essential.

E. Compliance with Standards and Regulations

Ensure that the selected capacitor cabinet meets relevant industry standards and local regulations to guarantee safety and reliability.

V. Conclusion

Capacitor cabinets play a vital role in enhancing the efficiency and reliability of electrical systems. Understanding the various product categories—fixed capacitor cabinets, automatic capacitor banks, harmonic filter capacitor cabinets, power factor correction panels, modular capacitor cabinets, and outdoor capacitor cabinets—enables users to make informed decisions based on their specific needs. By considering application requirements, environmental conditions, size constraints, budget, and compliance with standards, businesses can select the right capacitor cabinet to optimize their power management strategies.

VI. References

A. Suggested Reading and Resources

- IEEE Standards for Power Factor Correction

- Manufacturer Specifications and Technical Guides

B. Industry Standards and Guidelines

- National Electrical Manufacturers Association (NEMA) Guidelines

- International Electrotechnical Commission (IEC) Standards

In conclusion, capacitor cabinets are indispensable in modern electrical systems, and understanding their various categories and functionalities can lead to better energy management and cost savings.